A

Ash

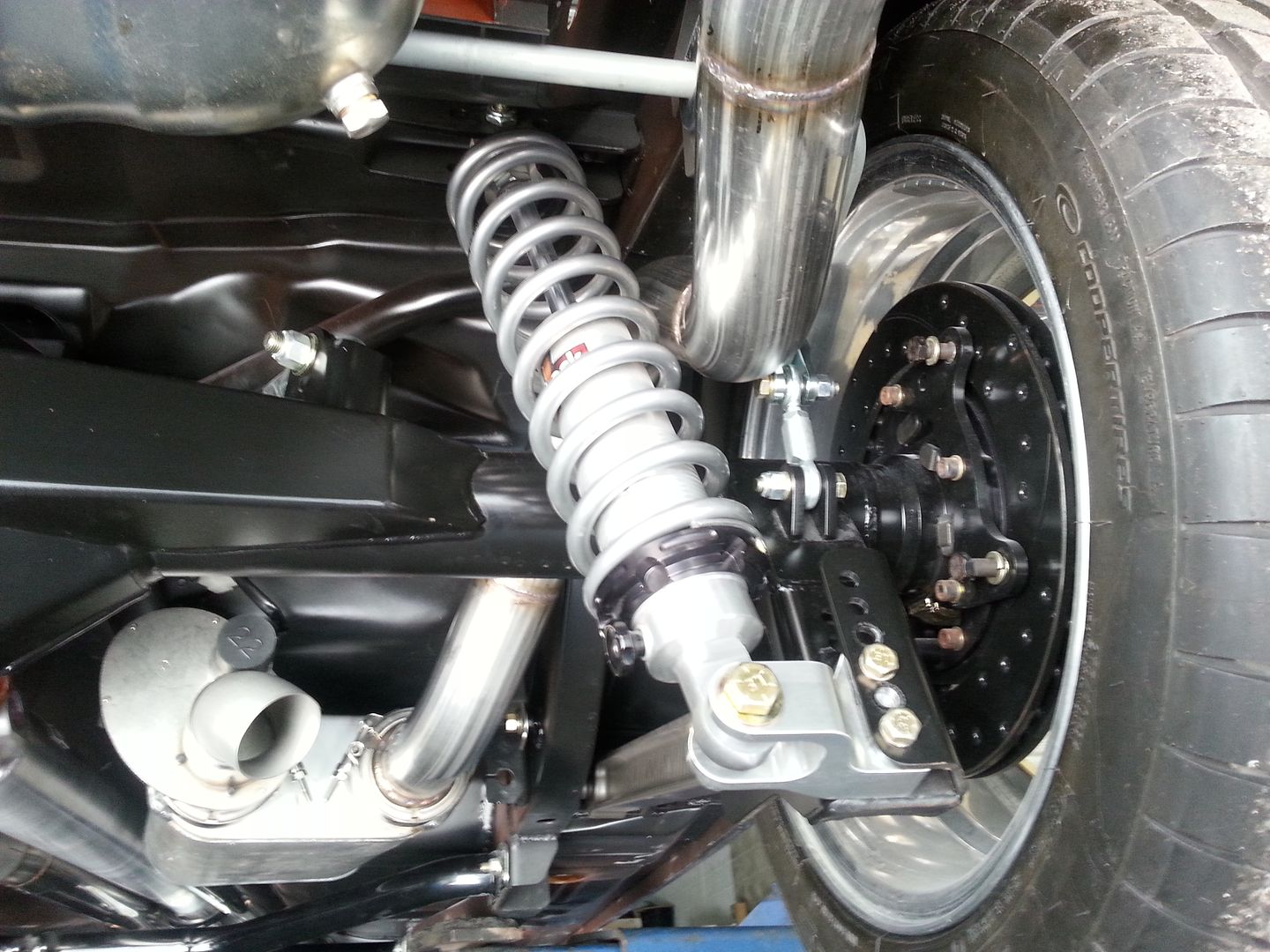

Hi Rusty, I am exploring options for subframe/body strengthening on my 69 Mustang and I knew I had seen some done by you before. I'm curious though what do you do with the exhaust on this set-up with the X-centre section?

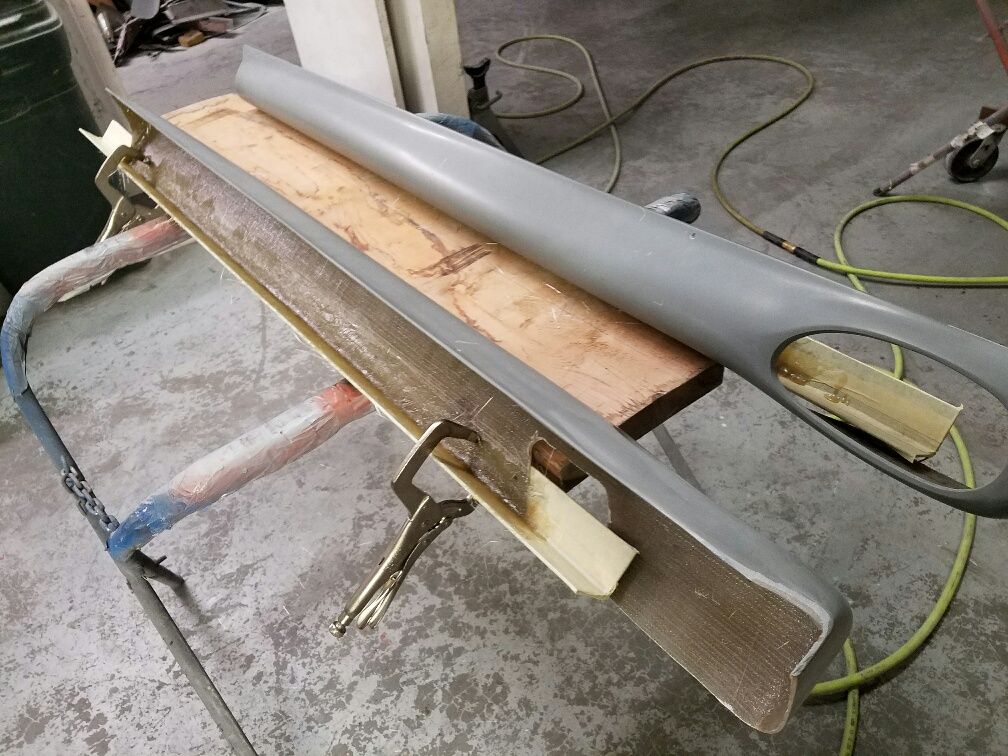

I think off the top of my head you have also put in convertible inner rockers on fastback/coupe bodies, is that correct? If so, what is involved and would you recommend it? At this point I have no floor pan in my car but am getting close to the point of welding in the new one piece replacement part. So now is the time to make any changes which I feel is necessary as I'm putting in an EFI 462CJ stroker engine.

Cheers,

Ash

I think off the top of my head you have also put in convertible inner rockers on fastback/coupe bodies, is that correct? If so, what is involved and would you recommend it? At this point I have no floor pan in my car but am getting close to the point of welding in the new one piece replacement part. So now is the time to make any changes which I feel is necessary as I'm putting in an EFI 462CJ stroker engine.

Cheers,

Ash

rusty428cj;n39457 said: