sprint_9

Rookie

Got my exhaust finished up, I believe Im back to where I need to be with my tips so my box will fit. I got all of the exhaust back together only to decide to tear it back apart in order to install a couple additional o2 sensor ports for tuning purposes. Im planning on doing that sometime this coming week. All these little rework projects are adding up to a lot of time

I also sent off my injectors and got word back they cleaned up good. He said cylinders 6 & 8 were stuck, with the others showing flow loss. All of that has been remedied with the cleaning so I am glad I sent all of them as a set. Im pretty excited to get it back together and try running it again, I think its safe to expect quite a difference.

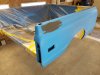

I started and finished buffing the inside of my box. I sanded it with some 2000 and then buffed, in hindsight I should have maybe gone a little more aggressive sanding as I have a little urethane wave. I wanted to stay on the light side of things as its a pain to buff with all the raised body lines. All things considered it looks pretty good for the inside, I plan on going more aggressive on the outside since it will be easier to work with. I set my wood in to see how it looked and I have to say Im thrilled. It finally felt like all of the hard work Ive put into this box has started to pay off, it feels like Ive been working on this box for a lifetime, lol, still have a long way to go too.

I also sent off my injectors and got word back they cleaned up good. He said cylinders 6 & 8 were stuck, with the others showing flow loss. All of that has been remedied with the cleaning so I am glad I sent all of them as a set. Im pretty excited to get it back together and try running it again, I think its safe to expect quite a difference.

I started and finished buffing the inside of my box. I sanded it with some 2000 and then buffed, in hindsight I should have maybe gone a little more aggressive sanding as I have a little urethane wave. I wanted to stay on the light side of things as its a pain to buff with all the raised body lines. All things considered it looks pretty good for the inside, I plan on going more aggressive on the outside since it will be easier to work with. I set my wood in to see how it looked and I have to say Im thrilled. It finally felt like all of the hard work Ive put into this box has started to pay off, it feels like Ive been working on this box for a lifetime, lol, still have a long way to go too.