Hi, my name is Mariano. I live in Argentina and I like to work on cars as a hobby.

Now, I am doing a panel repair in a rear lower corner.

I have been researching on the net and this forum has been very useful to me. I have read a lot of post here, but I thought that it would be a good idea to write myself a post to know your opinion on the following. I wish you could kindly advice me.

The rear lower corner and the inner wheel arch panel were rusted at the wheel arch corner as you can see in the following photos.

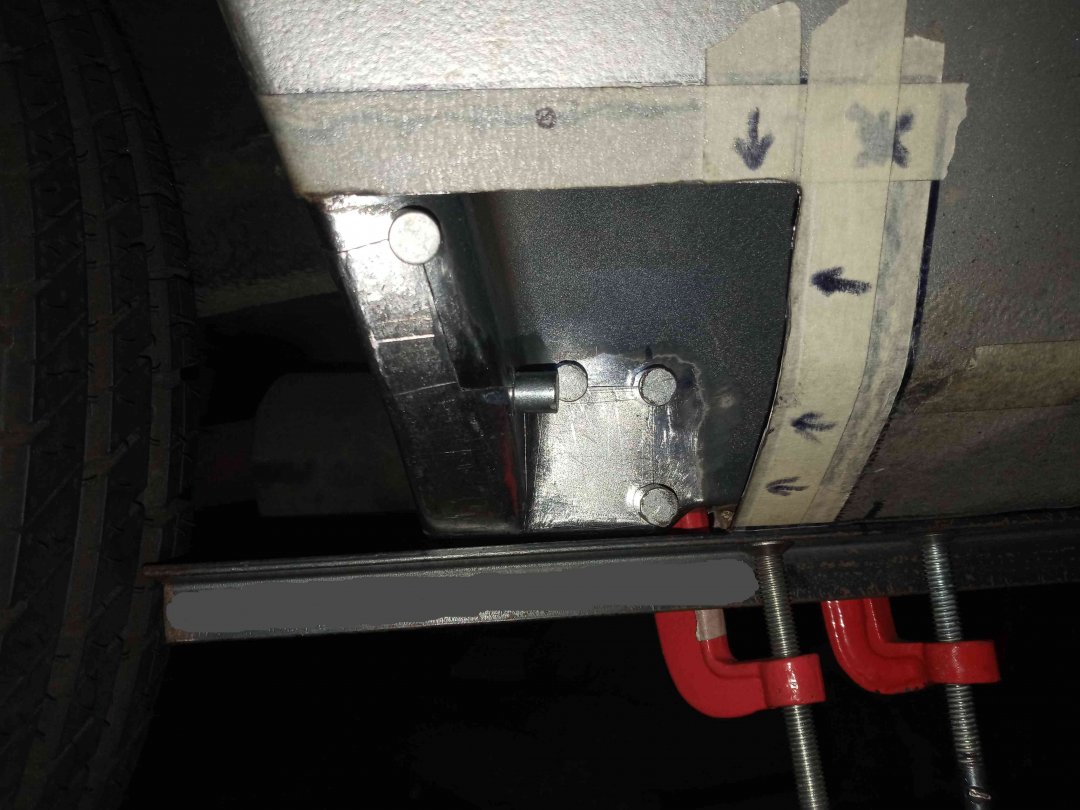

I have already cut those sections and made repair panels for them. Please, see inner repair panel in position for welding.

The question is because there is still some rust in the spot-welded lap joint zone between inner and outer panels. I cleaned the rust as well as I could with wire brushes, sand paper, scotch brite, etc but some rust remains as it is quite an inaccessible area.

I was thinking about soaking the complete section in phosphoric acid, then rinsing it with water and drying it. In some webpages I read that after soaking a spot-welded lap joint in phosphoric acid it would be impossible to remove the phosphoric acid completely and that the remaining phosphoric acid would continue to eat the good metal afterwards. What do you think? Please, see the following photos taken from the wheel arch side and from inside the trunk.

I am thinking about two ways to proceed:

1) Sanding the surface with 80 grit sand paper, cleaning and degreasing the surface, and applying epoxy primer as it is now. There is tight rust only and mainly surface rust, but there are also pits.

2) Soaking the hole zone (rear lower corner) in phosphoric acid, rinsing with water, drying it very well and applying epoxy primer.

What do you think? Your opinion will be highly appreciated.

Now, I am doing a panel repair in a rear lower corner.

I have been researching on the net and this forum has been very useful to me. I have read a lot of post here, but I thought that it would be a good idea to write myself a post to know your opinion on the following. I wish you could kindly advice me.

The rear lower corner and the inner wheel arch panel were rusted at the wheel arch corner as you can see in the following photos.

I have already cut those sections and made repair panels for them. Please, see inner repair panel in position for welding.

The question is because there is still some rust in the spot-welded lap joint zone between inner and outer panels. I cleaned the rust as well as I could with wire brushes, sand paper, scotch brite, etc but some rust remains as it is quite an inaccessible area.

I was thinking about soaking the complete section in phosphoric acid, then rinsing it with water and drying it. In some webpages I read that after soaking a spot-welded lap joint in phosphoric acid it would be impossible to remove the phosphoric acid completely and that the remaining phosphoric acid would continue to eat the good metal afterwards. What do you think? Please, see the following photos taken from the wheel arch side and from inside the trunk.

I am thinking about two ways to proceed:

1) Sanding the surface with 80 grit sand paper, cleaning and degreasing the surface, and applying epoxy primer as it is now. There is tight rust only and mainly surface rust, but there are also pits.

2) Soaking the hole zone (rear lower corner) in phosphoric acid, rinsing with water, drying it very well and applying epoxy primer.

What do you think? Your opinion will be highly appreciated.