You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Epoxy looks like solvent pop

- Thread starter Jerry1964

- Start date

Chris_Hamilton

Trying to be the best me, I can be

More than likely dirt, trash etc. Solvent pop leaves a very small crater. I don't know if epoxy is even capable of solvent pop.Sprayed 3 parts today they looked good as they were drying started to notice very fine almost like very fine sand in the epoxy doesn’t look like solvent pop but have never happened to me with epoxy before.

'68 Coronet R/T

Oldtimer

Has it been sitting a long time before use?

If so it may not have been stirred long enough to get everything properly dissolved. Never had this problem myself so not sure why it's happening to you?

If so it may not have been stirred long enough to get everything properly dissolved. Never had this problem myself so not sure why it's happening to you?

jcclark

Oldtimer

I get this all the time, maybe my activator is to old, I don't know but I usually sand it smoothSprayed 3 parts today they looked good as they were drying started to notice very fine almost like very fine sand in the epoxy doesn’t look like solvent pop but have never happened to me with epoxy before.

and go on and never had a problem.

Other brands of epoxy have done the same thing, and I only get it with epoxy, no other

primers or paints have it.

I've tried everything to strain it out, it's way to fine for any strainers I've found, like you said,

it's like fine sand, barely noticeable.

I don't think it's a problem.

jcclark

Oldtimer

Interesting, I know that's not my problem though,Epoxy can do that if it's been exposed to below freezing temperatures for too long during storage.

I keep all my paint products in my basement in colder weather,

and even if I didn't, my garage never gets below freezing inside, maybe 40 in extreme cold.

Must be something else.

I don't use epoxy a lot so my activator can be more than a year old, maybe that?

I don't worry about it, I've been using it for years like that.

Always worked fine, I just have to lightly sand it first.

dhutton01

Backyard Hack

Did you use waterborne wax and grease remover?I had the same thing happen this week spraying black. I'll try to get a picture of it next time. In my case I'm guessing its an operator error, maybe poor atomization? I might try using my Iwata 400 and see what happens.

Don

DanMcG

Promoted Users

Yes Don, maybe 2 hours before painting.Did you use waterborne wax and grease remover?

Don

dhutton01

Backyard Hack

People think I’m crazy but I have seen solvent pop with epoxy after waterborne wax and grease remover several times now. Never used to….Yes Don, maybe 2 hours before painting.

Don

MJM

Promoted Users

People think I’m crazy but I have seen solvent pop with epoxy after waterborne wax and grease remover several times now. Never used to….

Don

What are you using to clean before epoxy?

dhutton01

Backyard Hack

Bare metal I use solvent. If I use waterborne I let it dry overnight with some air flowing over it, especially body filler….What are you using to clean before epoxy?

Keep in mind I’m just a backyard hack sharing my experience here….

Don

MJM

Promoted Users

Bare metal I use solvent. If I use waterborne I let it dry overnight with some air flowing over it, especially body filler….

Keep in mind I’m just a backyard hack sharing my experience here….

Don

Thank you, dually noted. Oh and if you're a backyard hack (which I no you're not), then I'm a destroyer of all things good, lol

MJM

Promoted Users

it has done it for years. i think its just the pigment clumps together a little. doesnt hurt anything

In my short time of using the epoxy, I agree with your statement. Sometimes I get those little spots. More times than not, I don't. Either way it doesn't bother me since it's either getting sanded, or being sprayed over with 2k.

My only concern with those little defects will be when spraying the epoxy as a sealer. Granted the sealer will be reduced so, I hoping that will solve any issues.

crashtech

Combo Man & Mod

I use 125 micron strainers for sealer. Seems to have eliminated any concern about particles of any kind in the sealer.

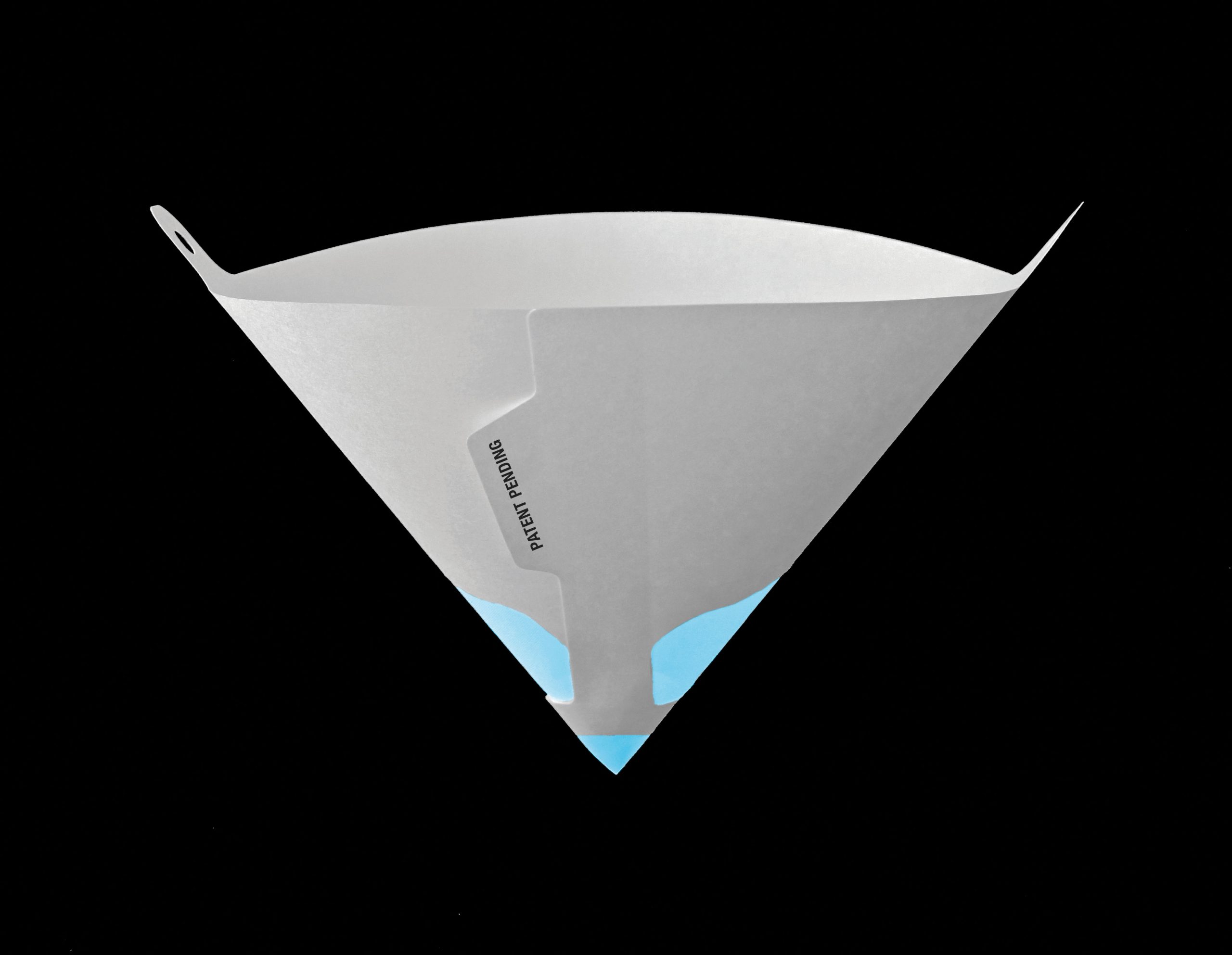

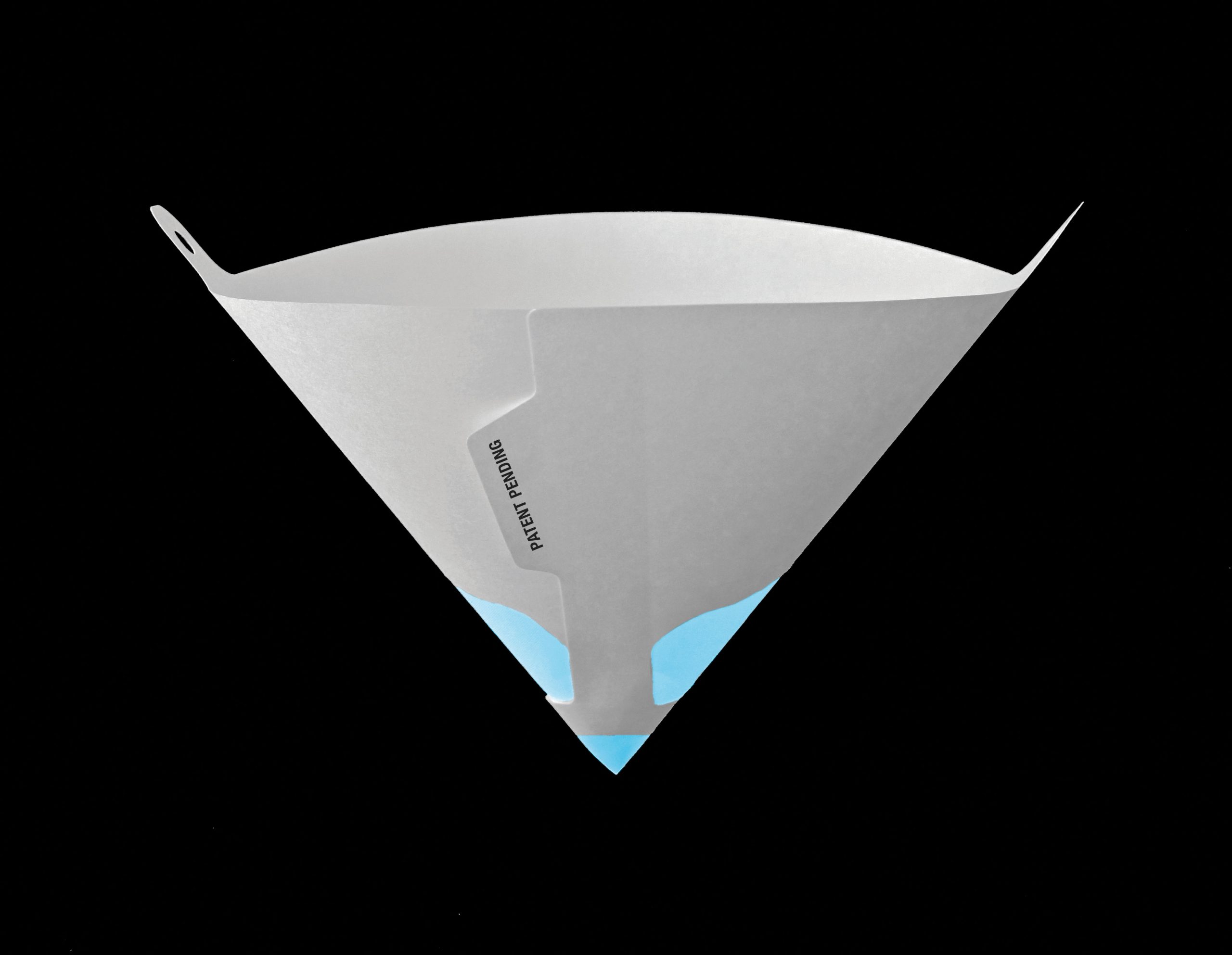

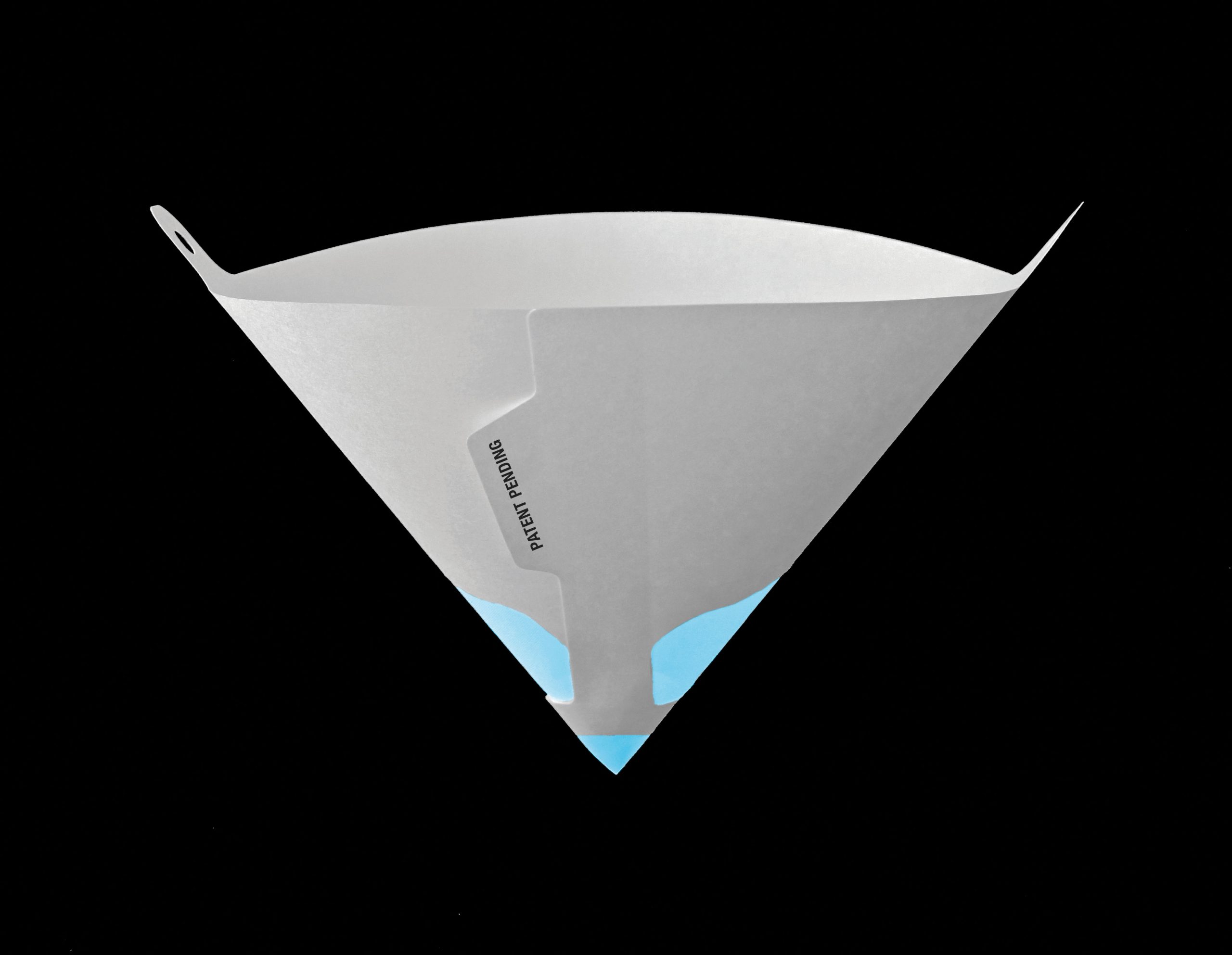

Gerson EliteTM Paint Strainers - 125 micron - Gerson

• “No touch” contamination-free storage and dispensing of strainers. • Pre-packed pods load directly into Elite Dispenser (color coded mesh only). • Automated production with triple-cleaned mesh assures highest level of filter purity. • Color-coded filter for easy identification of micron size...

www.gersonco.com

MJM

Promoted Users

I use 125 micron strainers for sealer. Seems to have eliminated any concern about particles of any kind in the sealer.

Gerson EliteTM Paint Strainers - 125 micron - Gerson

• “No touch” contamination-free storage and dispensing of strainers. • Pre-packed pods load directly into Elite Dispenser (color coded mesh only). • Automated production with triple-cleaned mesh assures highest level of filter purity. • Color-coded filter for easy identification of micron size...www.gersonco.com

Saved your suggestion for later use.

Thank you,