Chevman brought this to our attention in this other thread:

http://www.spiuserforum.com/showthread.php?2603-Correct-prep-before-SPI-epoxy-primer&p=38304#post38304

And he sent me some to do some testing. I've been in touch with the chemist that developed Phix and asked if there's any precautions using this product, he responded with the following:

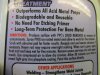

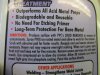

I formulated this product in August 1982, and began selling it in September 1982. Since that time we have had body shops and manufacturers across the U.S. using this product to prepare all metals for painting or processing.

Phix will dissolve red (flash) rust usually within several minutes, and will protect the steel or iron indefinitely while awaiting the next step, epoxy primer. I use PPG's DP series. It will also allow anyone to remove more serious rust by following the directions and referring to the videos on our website.

One basic step MUST be followed - remove all wet residue as the directions say, using paper towels (VIVA recommended).

NEVER apply body filler or any polyester-based primer over PHIX - it won't stick! ALWAYS apply epoxy primer, then filler or polyester-based high-build primer.

There is no rush after treating metal with PHIX. I recently painted a car that had sat in my shop for 19 years without paint. I merely wiped with prep solvent and fnally applied epoxy primer, etc., with no problems.

Hopefully this gives you some insight into the versatility of our product. Unfortunately there are a lot of hard-headed people who will never get the point, but the ones who do love us for this product!

You should find the adhesion for PHIX to be outstanding, as others have found a 30-80% greater adhesion factor for various paint systems.

Besides owning PPC and having formulated every product for us and others under private contract (I have 47 years as a chemist) I have been restoring cars for over 52 years abnd have been doing nothing but total frame-off work since 1984.