bigmoparjeff

New Member

It looks like I have a disaster in the making, so I thought I would post about it here to try to find out what I did wrong and to see if anyone had any tips on remedying the situation.

Here's what I did, in order, with times:

Thursday 12/16 around noon, I mixed up my sealer. White SPI epoxy, reduced 20% with PPG DT870. All components were in the house at 68 degrees F. After sitting for a while you could see it separating, so I would give it a stir every so often whenever I would walk by.

I decided to do a better masking job than originally planned, so it was around 8pm by the time I began spraying on the sealer. Shop temp was 68 degrees when spraying. I set the temp down to 65 and walked away at 9PM.

Friday 12/17 around 1pm shop temp was brought up to 68, then the heater shut off. I tacked off the epoxy and started spraying base. I was using PPG Shop Line base and it doesn't cover all that well, so I ended up running out of paint. I ran back to the jobber and got another quart. Place is local, so the round trip took less than an hour. Shot on one more coat of base, let it sit for 45 minutes, then applied one fairly heavy coat of clear. I left the shop around 5pm, temp was about 60. I left to visit friends as I usually do on Friday evenings. I returned to the shop at 1am. Temp was in the mid 50's. I turned the heat back on, set to 65, and let it run till Saturday evening at 6pm.

Everything seemed to be fine. The truck will not be garaged and it will driven in salt, so longevity is the number one priority on this project. The bottom of the cab got a heavy coat of bedliner for protection.

I managed to get some bedliner overspray on the paint, and when I tried to pick it off, the paint came off of the epoxy instead of the bedliner coming off of the paint. Further experimenting showed that I can choose any spot and scrape the paint off with my fingernail.

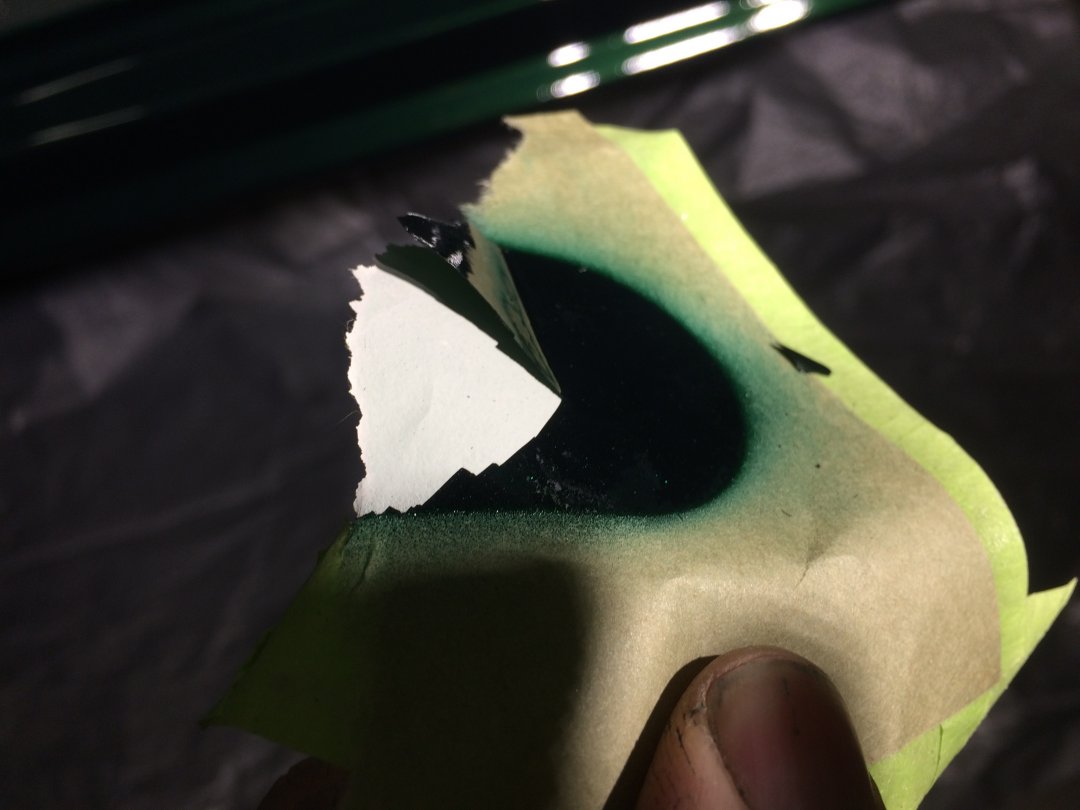

It was very easy to peel the paint off of this piece of masking paper.

The truck belongs to a friend of mine. It's a project that has gone way beyond the original plan, and I should have never gotten involved with in the first place. Getting the jambs painted and underside coated was to be a huge milestone and a time to celebrate and instead the thought of having to get all the paint back off and redoing it is making me sick.

Any thoughts, suggestions, advice will be greatly appreciated.

Thanks, Jeff

Here's what I did, in order, with times:

Thursday 12/16 around noon, I mixed up my sealer. White SPI epoxy, reduced 20% with PPG DT870. All components were in the house at 68 degrees F. After sitting for a while you could see it separating, so I would give it a stir every so often whenever I would walk by.

I decided to do a better masking job than originally planned, so it was around 8pm by the time I began spraying on the sealer. Shop temp was 68 degrees when spraying. I set the temp down to 65 and walked away at 9PM.

Friday 12/17 around 1pm shop temp was brought up to 68, then the heater shut off. I tacked off the epoxy and started spraying base. I was using PPG Shop Line base and it doesn't cover all that well, so I ended up running out of paint. I ran back to the jobber and got another quart. Place is local, so the round trip took less than an hour. Shot on one more coat of base, let it sit for 45 minutes, then applied one fairly heavy coat of clear. I left the shop around 5pm, temp was about 60. I left to visit friends as I usually do on Friday evenings. I returned to the shop at 1am. Temp was in the mid 50's. I turned the heat back on, set to 65, and let it run till Saturday evening at 6pm.

Everything seemed to be fine. The truck will not be garaged and it will driven in salt, so longevity is the number one priority on this project. The bottom of the cab got a heavy coat of bedliner for protection.

I managed to get some bedliner overspray on the paint, and when I tried to pick it off, the paint came off of the epoxy instead of the bedliner coming off of the paint. Further experimenting showed that I can choose any spot and scrape the paint off with my fingernail.

It was very easy to peel the paint off of this piece of masking paper.

The truck belongs to a friend of mine. It's a project that has gone way beyond the original plan, and I should have never gotten involved with in the first place. Getting the jambs painted and underside coated was to be a huge milestone and a time to celebrate and instead the thought of having to get all the paint back off and redoing it is making me sick.

Any thoughts, suggestions, advice will be greatly appreciated.

Thanks, Jeff