You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1964 Buick Riviera

- Thread starter 64Rivi

- Start date

64Rivi

Promoted Users

Happy New Year, all! Hope the holiday's found you all well.

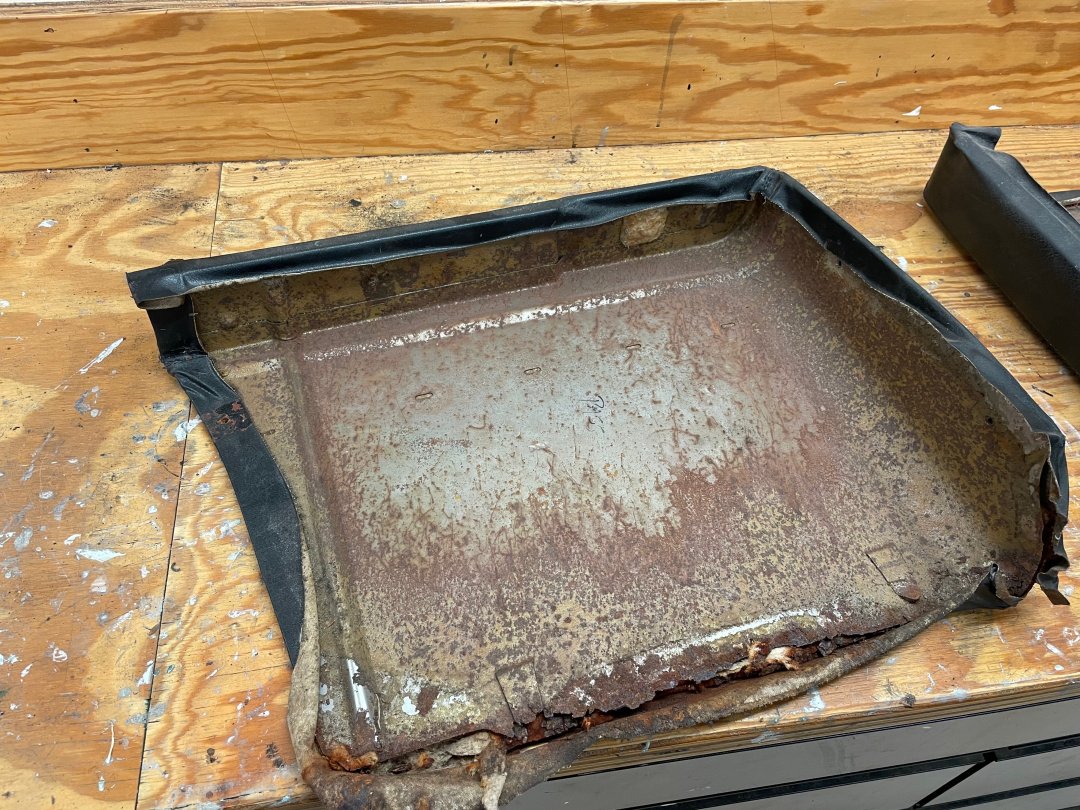

Still at it..... I've been keeping up the pace with the Buick but haven't had time to post the progress (ok; I've been too lazy ). Still plugging away at the interior. Next up were the door panels. The originals were completely shot. Nothing left to salvage on these.... The door cards were really beat up from moisture/ leaks over the years and even the steel edge band/ nail strips were rusted and twisted.

). Still plugging away at the interior. Next up were the door panels. The originals were completely shot. Nothing left to salvage on these.... The door cards were really beat up from moisture/ leaks over the years and even the steel edge band/ nail strips were rusted and twisted.

They do reproduce door panels for these care however -in keeping with my original goals- I wanted the entire interior to be leather so I had to start from scratch. Thankfully, new door cards are available and -better yet- so are the steel edge guards and nail strips. First order of business was to remove the steel components. These door panels have formed steel panels that attach to the top of the door cards to form the top contours of the door panels. The rear arm rests are also made of steel and were in rough shape. I removed the steel panels, blasted them and coated them all with epoxy before starting the door panels.

The rear arm rest were rotted along the bottom from water leaks and soaked carpets over the years. had to cut the bottoms off and replace the metal on one side but got lucky with the other. A few coats of epoxy to seal it all up.

The top panels were original pressed into the door cards with a punch that spreads open the steel as it opens up inside the card. Can't re-attach them the same way so aluminum rivets did the job nicely. After they were all set, I hammered them flat to make them flush. Once these are on, I was able to set them on the door and line it all up before marking out the upholstery.

Next, I used a thin layer of 1/8 closed cell foam to replace the original cotton and open cell polyurethane foam that was used for padding and bulking up some section on the door panel.

Then everything went back on the car for final fitment before the upholstery work started.

Still at it..... I've been keeping up the pace with the Buick but haven't had time to post the progress (ok; I've been too lazy

They do reproduce door panels for these care however -in keeping with my original goals- I wanted the entire interior to be leather so I had to start from scratch. Thankfully, new door cards are available and -better yet- so are the steel edge guards and nail strips. First order of business was to remove the steel components. These door panels have formed steel panels that attach to the top of the door cards to form the top contours of the door panels. The rear arm rests are also made of steel and were in rough shape. I removed the steel panels, blasted them and coated them all with epoxy before starting the door panels.

The rear arm rest were rotted along the bottom from water leaks and soaked carpets over the years. had to cut the bottoms off and replace the metal on one side but got lucky with the other. A few coats of epoxy to seal it all up.

The top panels were original pressed into the door cards with a punch that spreads open the steel as it opens up inside the card. Can't re-attach them the same way so aluminum rivets did the job nicely. After they were all set, I hammered them flat to make them flush. Once these are on, I was able to set them on the door and line it all up before marking out the upholstery.

Next, I used a thin layer of 1/8 closed cell foam to replace the original cotton and open cell polyurethane foam that was used for padding and bulking up some section on the door panel.

Then everything went back on the car for final fitment before the upholstery work started.

64Rivi

Promoted Users

Up next...it was time to make some patterns and cut up the cow!

Then the glue-up work on the door panels..

The front door panels have a carpet strip along the bottom. The carpet gets glued on the panel but has a vinyl edge stitched to it so it can wrap around the panel and dress the edge. I made this out of leather as well.

A thin molding bridges the gap between the leather panel and the carpet on the bottom.

And then finally......the wood panels get mounted!

Then the glue-up work on the door panels..

The front door panels have a carpet strip along the bottom. The carpet gets glued on the panel but has a vinyl edge stitched to it so it can wrap around the panel and dress the edge. I made this out of leather as well.

A thin molding bridges the gap between the leather panel and the carpet on the bottom.

And then finally......the wood panels get mounted!

'68 Coronet R/T

Oldtimer

Love the wood veneer work. It really sets things off.

Great job on this car.

Great job on this car.

64Rivi

Promoted Users

Thank you again for the kind words, guys.

And yes, Don; I can sew too! LOL. ......something stuck with home economics classes in school.

Clubairth; all new veneer. I replaced the original stuff with quarter-sawn Walnut (check out page 6 of this thread). And ditto on the leather smell, Mhinch...the garage smells awesome when the cover comes off. LOL

After the door panels, it was time to fix the arm rests. They have a steel arm rest with foam cast into it. Beneath that is a plastic fairing just for looks. The foam was in decent shape but some was worn by the hand pulls and had shrunk along the edges in some spots. Since these get a lot of movement and stress -and I needed a flat surface for the leather the lay right- I used filler to fill and reshape the missing foam. As for the plastic fairings, they had a lot cracks and one was almost broken in half. For those, I opened the cracks with a Dremel to make more surface area and filled them with urethane plastic adhesive. I left the adhesive alone on the backs but blocked it down pretty flat on the front so it wouldn't telegraph through the leather.

One those repairs were made....it was back to the glue and the leather....

And then mount them on the door panels.

Finally, time to get them set on the doors and add all the chrome details.

And yes, Don; I can sew too! LOL. ......something stuck with home economics classes in school.

Clubairth; all new veneer. I replaced the original stuff with quarter-sawn Walnut (check out page 6 of this thread). And ditto on the leather smell, Mhinch...the garage smells awesome when the cover comes off. LOL

After the door panels, it was time to fix the arm rests. They have a steel arm rest with foam cast into it. Beneath that is a plastic fairing just for looks. The foam was in decent shape but some was worn by the hand pulls and had shrunk along the edges in some spots. Since these get a lot of movement and stress -and I needed a flat surface for the leather the lay right- I used filler to fill and reshape the missing foam. As for the plastic fairings, they had a lot cracks and one was almost broken in half. For those, I opened the cracks with a Dremel to make more surface area and filled them with urethane plastic adhesive. I left the adhesive alone on the backs but blocked it down pretty flat on the front so it wouldn't telegraph through the leather.

One those repairs were made....it was back to the glue and the leather....

And then mount them on the door panels.

Finally, time to get them set on the doors and add all the chrome details.

64Rivi

Promoted Users

Thank you, pugsy!

Moving onto the package tray, I got pretty lucky from the previous owner (about the only time...). These had pretty flat and boring package trays. Somewhere in the past, someone made this package tray from fiberglass and molded in these really nice haunches behind the rear seats. I've never seen one like it for the Rivi but it has great style to it. It also has a curvature to it and doesn't lay flat like the original.

After stripping the old vinyl, felt and adhesive, I had to do a bunch of repair to the fiberglass where the fasteners go through to mount it. Once that was done it was time for the leather work....again.

Since it is a pretty rough fiberglass lay-up, I covered it with 1/8 foam to get a flat and true surface.

Then the leather went on.....this one was fun......

And then it was back in the car along with the rest of the filler panels along the edges. While I did this, I installed all new felt on the wheel tubs for sound deadening (just like factory) and also made a new trunk divider out of masonite. It's amazing how much quieter it got in the car after doing this. Not to mention how hard you have to close the trunk to get it to latch now. LOL.

Moving onto the package tray, I got pretty lucky from the previous owner (about the only time...). These had pretty flat and boring package trays. Somewhere in the past, someone made this package tray from fiberglass and molded in these really nice haunches behind the rear seats. I've never seen one like it for the Rivi but it has great style to it. It also has a curvature to it and doesn't lay flat like the original.

After stripping the old vinyl, felt and adhesive, I had to do a bunch of repair to the fiberglass where the fasteners go through to mount it. Once that was done it was time for the leather work....again.

Since it is a pretty rough fiberglass lay-up, I covered it with 1/8 foam to get a flat and true surface.

Then the leather went on.....this one was fun......

And then it was back in the car along with the rest of the filler panels along the edges. While I did this, I installed all new felt on the wheel tubs for sound deadening (just like factory) and also made a new trunk divider out of masonite. It's amazing how much quieter it got in the car after doing this. Not to mention how hard you have to close the trunk to get it to latch now. LOL.

Dean Jenkins

Promoted Users

What he said!Friggen nice job of it.

JimKueneman

Mopar Nut

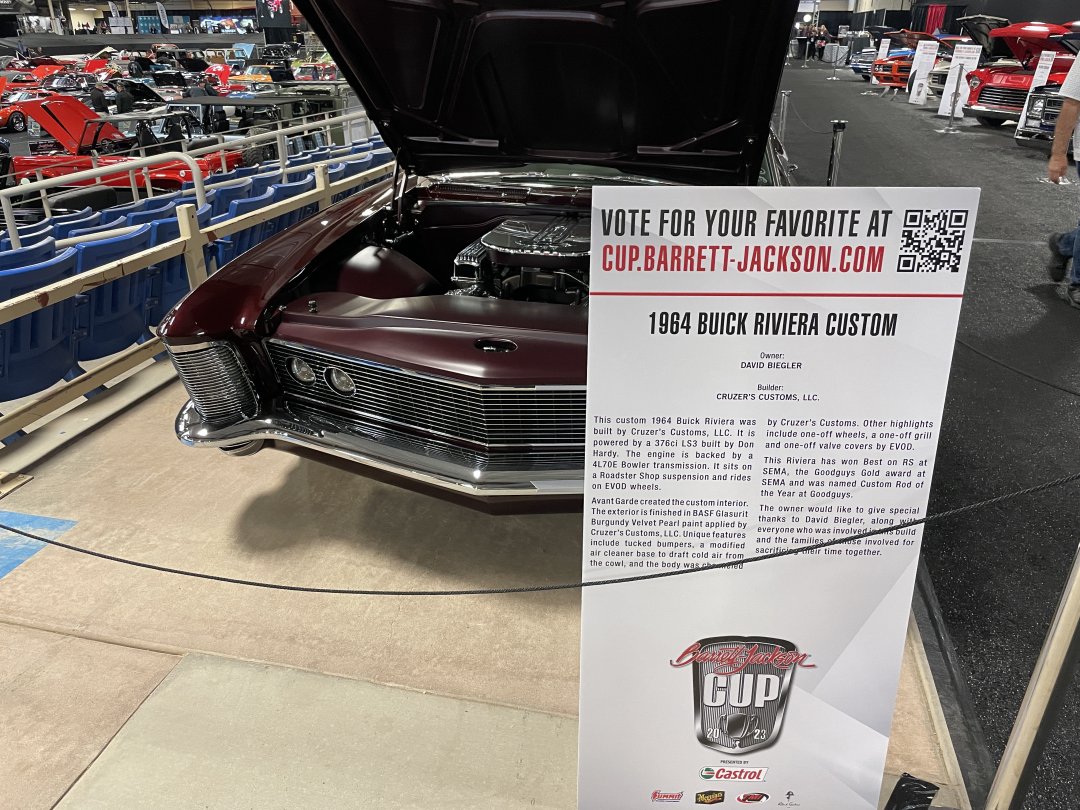

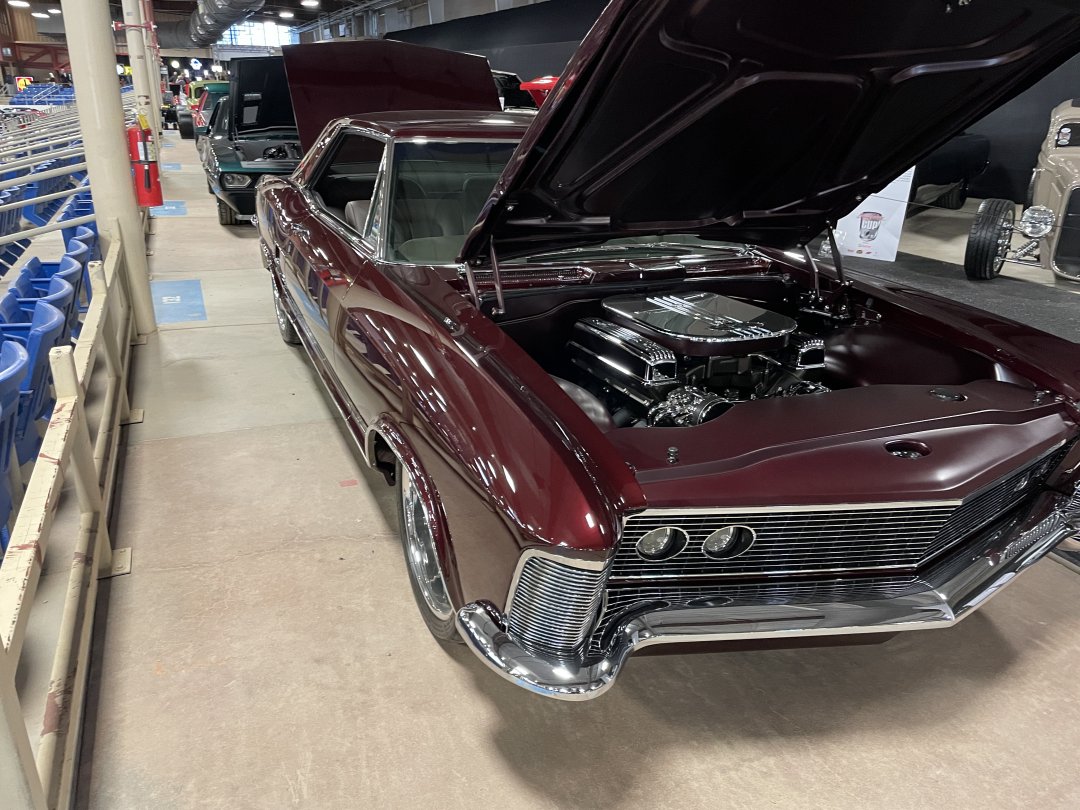

Barrett Jackson today.

64Rivi

Promoted Users

That's a beautiful Riviera Resto-mod. They call it "Vanquish" and was built by Cruzer Customs (I think it was a SEMA build). Lots of detail on that one (and a boat load of work). Detroit Speed also built a 65' Resto-Mod Riviera but much more subdued with a lot of small details that most would not pick up on unless you watched their video (or are a Riviera nut!).

I agree with Crash on the engine. The LS thing is cool and it's nice that they go the extra mile to make it look like a Buick Nailhead....however, the Nailhead is a huge part of these cars. It's a shame to take them out (IMO). I get it...but the more I've worked on this car over the years, the more and more I come to believe this is one of few cars that damn near reached the pinnacle of automotive design (for the record, they go on my list with the 69' Z28 Camaro and 57' Chevy Bel Air). It seems like the more you try to modify these cars, the more it takes away from the original design genius that went into them.....but yes; opinions are like a$$-holes....everyone's got one.....including me......I might even have two!

Still playing catch up here. Up next; the dash pad.

The vinyl was completely shot; dry-rotted, crack and falling apart (which is usual for these cars). These are steel frames with foam formed in-place and then vacuumed covered with vinyl. Started off by carefully removing the vinyl with heat....and one small piece at a time.....in order to salvage the foam underneath......tedious.

Once It was all removed, I taped off the foam and blasted the metal. After that, gave it a couple of wet coat of SPI epoxy including the foam in order to seal it and stabilize/ glue together the porous foam on the surface.

The foam was actually in good shape considering how old it is and how bad the vinyl was. The original foam had some voids in it and some pulled out when I was removing the vinyl. In order to wrap this in leather, it has to be a good, flat foundation or it will all telegraph through and look like crap. Again, I didn't want to add any padding to level it out since it will take away from the original look of the interior. I was going for subtle with the leather on this car.

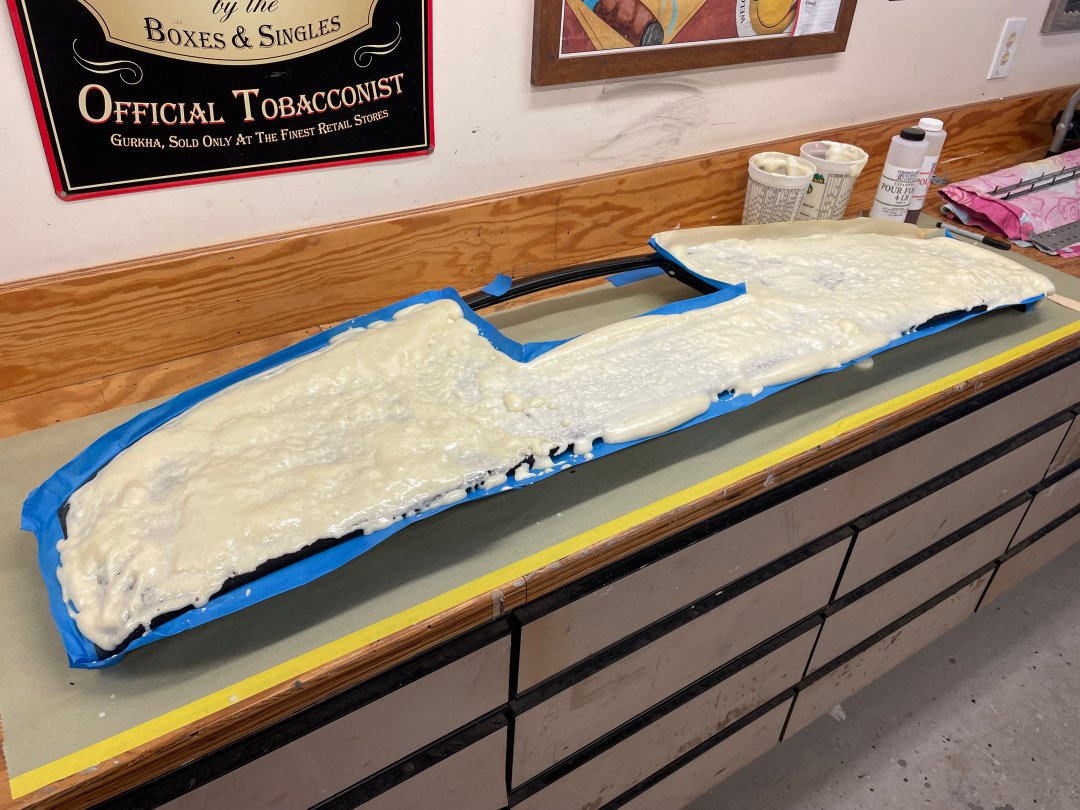

So a big thanks to Jim Kueneman for the next step. I used the method he posted on the Valiant dashboard using the pourable foam. I built a tape-dam around the edges and poured a 4 oz. two-part urethane foam over the top. Truth be told, I first started experimenting with a 14 oz. foam to duplicate the same density that the dash is made from......not a good idea. You cannot shape that foam easily since it is very soft and pliable. I actually had to grind it out of a few spots I tested it on in order to get it out.

As Jim noted, you can grind this down pretty quickly with a 60 grit disk but it's like trying to shape a rice cake...it goes way too fast and you have to be careful or it will disappear before your eyes. I opted to go at it by hand with a cheese grater file. More work but it worked nicely as you really couldn't mess it up. Once you hit the original foam, it just glides across the higher density foam and keeps you from going too far.

After the heavy stuff was knocked down, I switched to a block with 60-grit paper to finish shape it.

And while it filled all the heavy stuff and did a great job for vinyl.....leather needed a bit more. I then skim coated it with filler to get the remaining voids that the foam could not fill. Blocked that down again and covered with with 3 -4 wet coats of SPI epoxy to seal it up for good.

Time for the leather. This was another fun one! Between the tapers and transitions on the side and the wrap around the front edge, this got interesting. Lots of steam and patience to get this to land right.

And then back in the car to finish off the dash. Again; darn near design perfection on this car!

I agree with Crash on the engine. The LS thing is cool and it's nice that they go the extra mile to make it look like a Buick Nailhead....however, the Nailhead is a huge part of these cars. It's a shame to take them out (IMO). I get it...but the more I've worked on this car over the years, the more and more I come to believe this is one of few cars that damn near reached the pinnacle of automotive design (for the record, they go on my list with the 69' Z28 Camaro and 57' Chevy Bel Air). It seems like the more you try to modify these cars, the more it takes away from the original design genius that went into them.....but yes; opinions are like a$$-holes....everyone's got one.....including me......I might even have two!

Still playing catch up here. Up next; the dash pad.

The vinyl was completely shot; dry-rotted, crack and falling apart (which is usual for these cars). These are steel frames with foam formed in-place and then vacuumed covered with vinyl. Started off by carefully removing the vinyl with heat....and one small piece at a time.....in order to salvage the foam underneath......tedious.

Once It was all removed, I taped off the foam and blasted the metal. After that, gave it a couple of wet coat of SPI epoxy including the foam in order to seal it and stabilize/ glue together the porous foam on the surface.

The foam was actually in good shape considering how old it is and how bad the vinyl was. The original foam had some voids in it and some pulled out when I was removing the vinyl. In order to wrap this in leather, it has to be a good, flat foundation or it will all telegraph through and look like crap. Again, I didn't want to add any padding to level it out since it will take away from the original look of the interior. I was going for subtle with the leather on this car.

So a big thanks to Jim Kueneman for the next step. I used the method he posted on the Valiant dashboard using the pourable foam. I built a tape-dam around the edges and poured a 4 oz. two-part urethane foam over the top. Truth be told, I first started experimenting with a 14 oz. foam to duplicate the same density that the dash is made from......not a good idea. You cannot shape that foam easily since it is very soft and pliable. I actually had to grind it out of a few spots I tested it on in order to get it out.

As Jim noted, you can grind this down pretty quickly with a 60 grit disk but it's like trying to shape a rice cake...it goes way too fast and you have to be careful or it will disappear before your eyes. I opted to go at it by hand with a cheese grater file. More work but it worked nicely as you really couldn't mess it up. Once you hit the original foam, it just glides across the higher density foam and keeps you from going too far.

After the heavy stuff was knocked down, I switched to a block with 60-grit paper to finish shape it.

And while it filled all the heavy stuff and did a great job for vinyl.....leather needed a bit more. I then skim coated it with filler to get the remaining voids that the foam could not fill. Blocked that down again and covered with with 3 -4 wet coats of SPI epoxy to seal it up for good.

Time for the leather. This was another fun one! Between the tapers and transitions on the side and the wrap around the front edge, this got interesting. Lots of steam and patience to get this to land right.

And then back in the car to finish off the dash. Again; darn near design perfection on this car!

JimKueneman

Mopar Nut

That's a beautiful Riviera Resto-mod. They call it "Vanquish" and was built by Cruzer Customs (I think it was a SEMA build). Lots of detail on that one (and a boat load of work). Detroit Speed also built a 65' Resto-Mod Riviera but much more subdued with a lot of small details that most would not pick up on unless you watched their video (or are a Riviera nut!).

I agree with Crash on the engine. The LS thing is cool and it's nice that they go the extra mile to make it look like a Buick Nailhead....however, the Nailhead is a huge part of these cars. It's a shame to take them out (IMO). I get it...but the more I've worked on this car over the years, the more and more I come to believe this is one of few cars that damn near reached the pinnacle of automotive design (for the record, they go on my list with the 69' Z28 Camaro and 57' Chevy Bel Air). It seems like the more you try to modify these cars, the more it takes away from the original design genius that went into them.....but yes; opinions are like a$$-holes....everyone's got one.....including me......I might even have two!

Still playing catch up here. Up next; the dash pad.

The vinyl was completely shot; dry-rotted, crack and falling apart (which is usual for these cars). These are steel frames with foam formed in-place and then vacuumed covered with vinyl. Started off by carefully removing the vinyl with heat....and one small piece at a time.....in order to salvage the foam underneath......tedious.

View attachment 23957

Once It was all removed, I taped off the foam and blasted the metal. After that, gave it a couple of wet coat of SPI epoxy including the foam in order to seal it and stabilize/ glue together the porous foam on the surface.

View attachment 23966

The foam was actually in good shape considering how old it is and how bad the vinyl was. The original foam had some voids in it and some pulled out when I was removing the vinyl. In order to wrap this in leather, it has to be a good, flat foundation or it will all telegraph through and look like crap. Again, I didn't want to add any padding to level it out since it will take away from the original look of the interior. I was going for subtle with the leather on this car.

So a big thanks to Jim Kueneman for the next step. I used the method he posted on the Valiant dashboard using the pourable foam. I built a tape-dam around the edges and poured a 4 oz. two-part urethane foam over the top. Truth be told, I first started experimenting with a 14 oz. foam to duplicate the same density that the dash is made from......not a good idea. You cannot shape that foam easily since it is very soft and pliable. I actually had to grind it out of a few spots I tested it on in order to get it out.

View attachment 23965

As Jim noted, you can grind this down pretty quickly with a 60 grit disk but it's like trying to shape a rice cake...it goes way too fast and you have to be careful or it will disappear before your eyes. I opted to go at it by hand with a cheese grater file. More work but it worked nicely as you really couldn't mess it up. Once you hit the original foam, it just glides across the higher density foam and keeps you from going too far.

View attachment 23964

View attachment 23963

After the heavy stuff was knocked down, I switched to a block with 60-grit paper to finish shape it.

View attachment 23962

And while it filled all the heavy stuff and did a great job for vinyl.....leather needed a bit more. I then skim coated it with filler to get the remaining voids that the foam could not fill. Blocked that down again and covered with with 3 -4 wet coats of SPI epoxy to seal it up for good.

View attachment 23961

Time for the leather. This was another fun one! Between the tapers and transitions on the side and the wrap around the front edge, this got interesting. Lots of steam and patience to get this to land right.

View attachment 23960

View attachment 23959

And then back in the car to finish off the dash. Again; darn near design perfection on this car!

View attachment 23958

Super cool. Great job. Glad I could help

64Rivi

Promoted Users

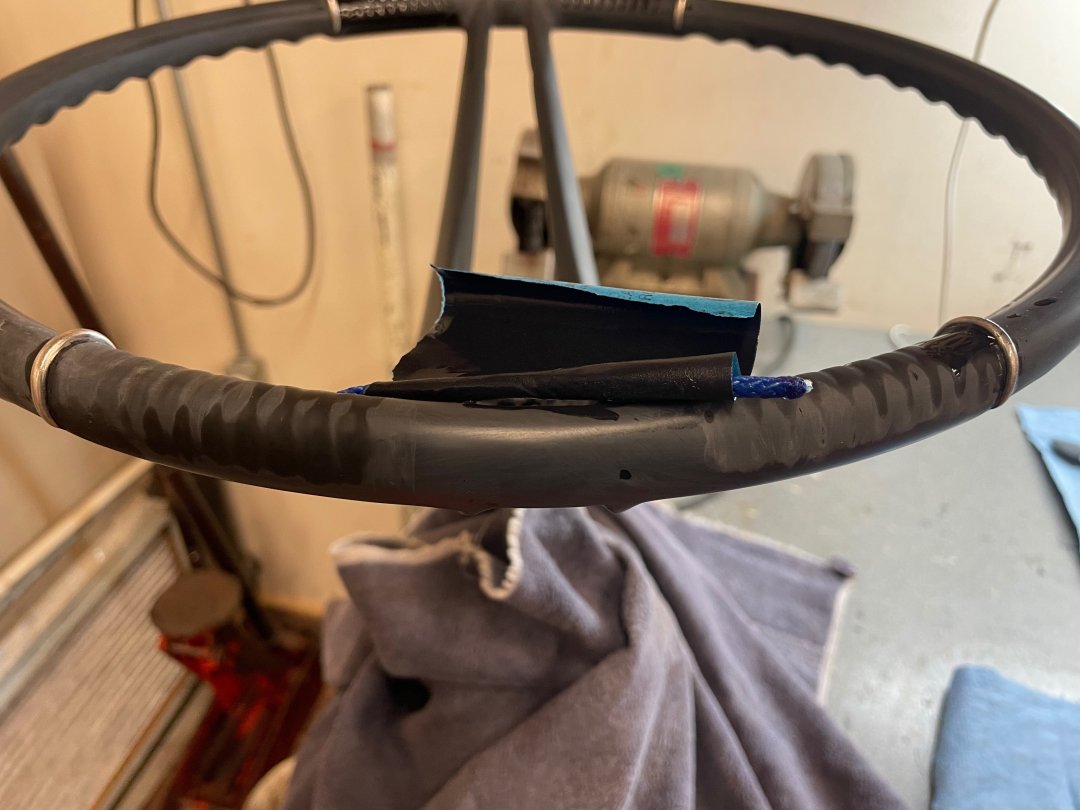

Up next was the steering wheel. Not in horrible shape overall compared to others but it still needed considerable repairs.

The wheel itself was solid with no cracks. All of the cracks were at the joints with the center section. Both at the hub and at the wheel. I dug out the old plastic and really opened each crack with a Dremel and a small carbide burr. Opened each area up wide to give it more surface area as well as down to the steel to make sure it was clean. Once the metal was cleaned up, it was given a few coats of epoxy with a brush.

After letting the epoxy cure a few days, I filled it all in with 3M 08237 semi-rigid urethane and gave that a day to cure. I initially knocked they heavy stuff down with 80-grit on a wheel and then switched over to 80-grit with various shapes to get in where I needed to and block it all flat. I went over the whole wheel with 80-grit to prep for epoxy.

After that, I spent literally hours detail wet sanding over a bucket....not fun! Had to get creative with the ribs on the wheel and found that some paracord worked pretty well.

Once that nightmare was over, I shot a coat of epoxy sealer followed by two coats of the SPI black base that was used on the car.

Followed that up with 2-coats of Universal and called it a day. Didn't want to go any more than that since I didn't plan on cutting and polishing it. The wheel has chrome beauty rings that are set into the wheel itself. I had those taped throughout. When finished, I taped each side of the wheel next to them and carefully polished them with a felt buff on a Dremel and some metal polish.

The wheel itself was solid with no cracks. All of the cracks were at the joints with the center section. Both at the hub and at the wheel. I dug out the old plastic and really opened each crack with a Dremel and a small carbide burr. Opened each area up wide to give it more surface area as well as down to the steel to make sure it was clean. Once the metal was cleaned up, it was given a few coats of epoxy with a brush.

After letting the epoxy cure a few days, I filled it all in with 3M 08237 semi-rigid urethane and gave that a day to cure. I initially knocked they heavy stuff down with 80-grit on a wheel and then switched over to 80-grit with various shapes to get in where I needed to and block it all flat. I went over the whole wheel with 80-grit to prep for epoxy.

After that, I spent literally hours detail wet sanding over a bucket....not fun! Had to get creative with the ribs on the wheel and found that some paracord worked pretty well.

Once that nightmare was over, I shot a coat of epoxy sealer followed by two coats of the SPI black base that was used on the car.

Followed that up with 2-coats of Universal and called it a day. Didn't want to go any more than that since I didn't plan on cutting and polishing it. The wheel has chrome beauty rings that are set into the wheel itself. I had those taped throughout. When finished, I taped each side of the wheel next to them and carefully polished them with a felt buff on a Dremel and some metal polish.

'68 Coronet R/T

Oldtimer

Thanks for the details. I took notes as my GTX steering wheel is going to need some work as well.