P

PUNISHER VETTE

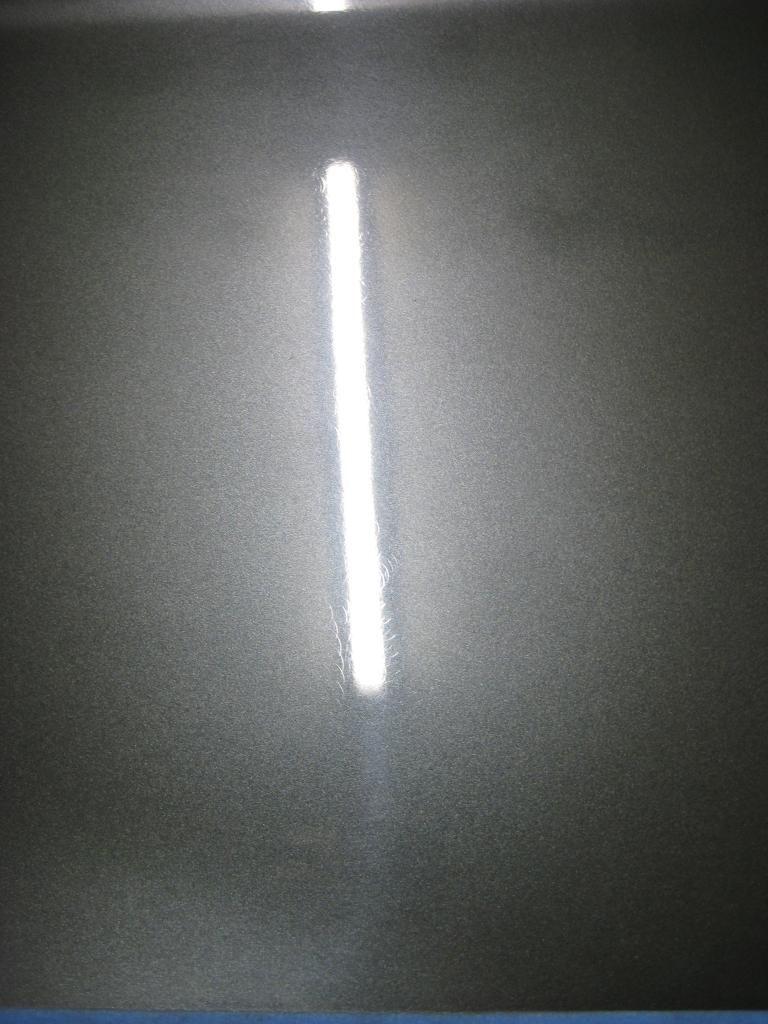

Sorry... I'm still learning and the way I learn is by doing... which I guess is a good thing that I started on the old hood that doesn't matter.

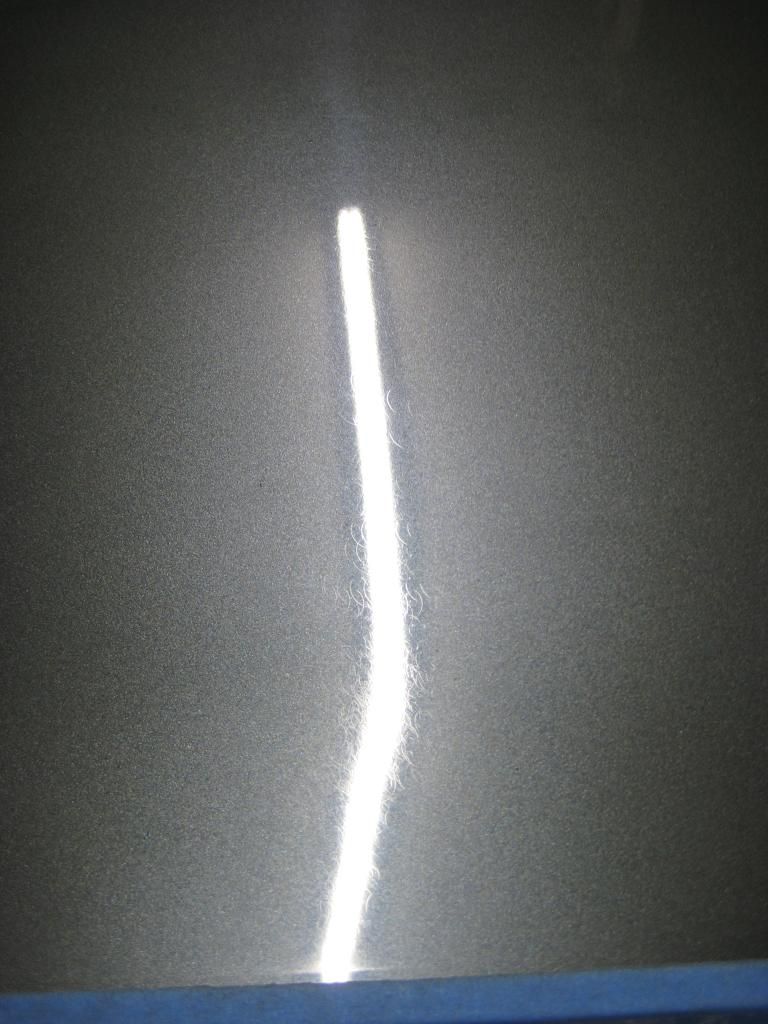

I quickly found out that sanding near an edge is NOT a good thing

Question1:

How should it be done the correct way to avoid this from happening?

-Use tape on the edge a cm or so onto the flat area?

-Do i just need to apply more pressure to the side of the DA that is going off the edge and be positive the side coming onto the edge has less pressure?

-Or should I avoid the edges all together with the DA and hand sand them?

I wasn't really paying too much attention when I did this...but it happened a lot easier than I expected. Mostly because the corner here bends down slightly so to get it sanded I probably went a little overboard on it. But this is a great learning experience so I'm not mad...Just don't want to be looked at like some idiot lol.

I started with 800g to cut the initial orange peal. This is 2 coats clear, 600 block sanded, 2 more coats clear.

Question 2:

would a 2nd block and 2 more coats of clear be a good thing for thicker clear and maybe straighter/deeper end result?)

I read some just do 2 coats and call it good, some do 2, bock, 2. some I saw do 3, block, 3.. Whats the best of the best that I should be doing? 2, block, 2, block, 2?

Question3:

If this does happen on the real thing and assuming I didn't burn through the metallic, (which I did here I believe), do you just shoot some more clear to save it? I guess if you burn through the metallic you have to spot fix it...which is way more than I want to so i'll just be more careful!

I quickly found out that sanding near an edge is NOT a good thing

Question1:

How should it be done the correct way to avoid this from happening?

-Use tape on the edge a cm or so onto the flat area?

-Do i just need to apply more pressure to the side of the DA that is going off the edge and be positive the side coming onto the edge has less pressure?

-Or should I avoid the edges all together with the DA and hand sand them?

I wasn't really paying too much attention when I did this...but it happened a lot easier than I expected. Mostly because the corner here bends down slightly so to get it sanded I probably went a little overboard on it. But this is a great learning experience so I'm not mad...Just don't want to be looked at like some idiot lol.

I started with 800g to cut the initial orange peal. This is 2 coats clear, 600 block sanded, 2 more coats clear.

Question 2:

would a 2nd block and 2 more coats of clear be a good thing for thicker clear and maybe straighter/deeper end result?)

I read some just do 2 coats and call it good, some do 2, bock, 2. some I saw do 3, block, 3.. Whats the best of the best that I should be doing? 2, block, 2, block, 2?

Question3:

If this does happen on the real thing and assuming I didn't burn through the metallic, (which I did here I believe), do you just shoot some more clear to save it? I guess if you burn through the metallic you have to spot fix it...which is way more than I want to so i'll just be more careful!