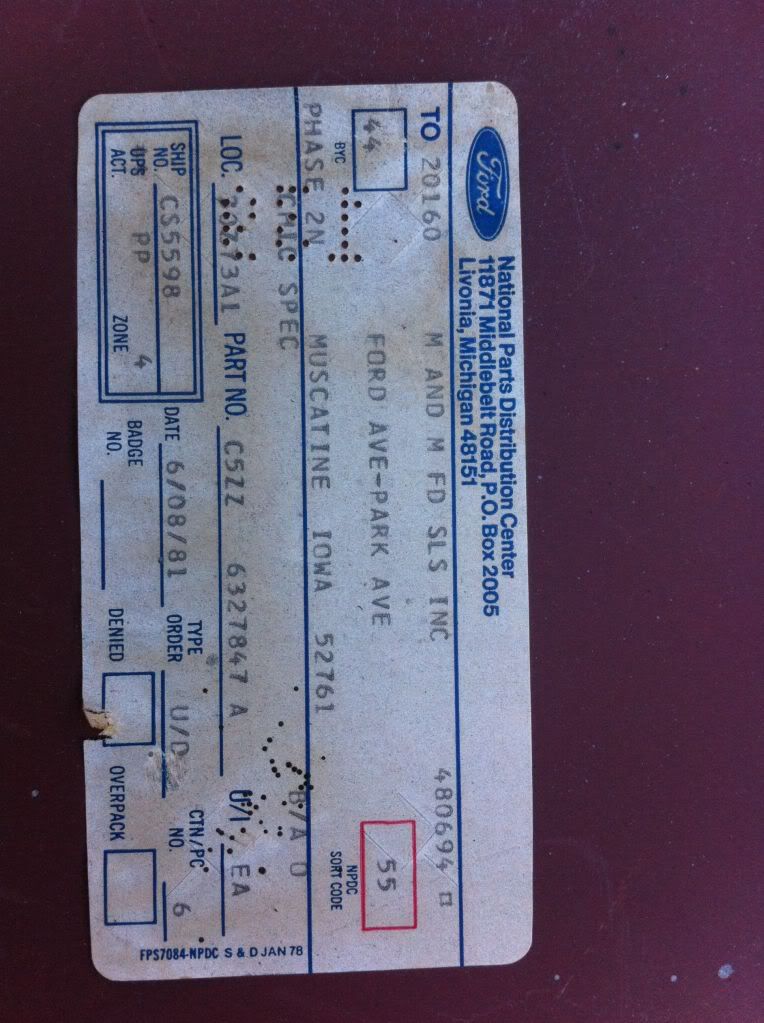

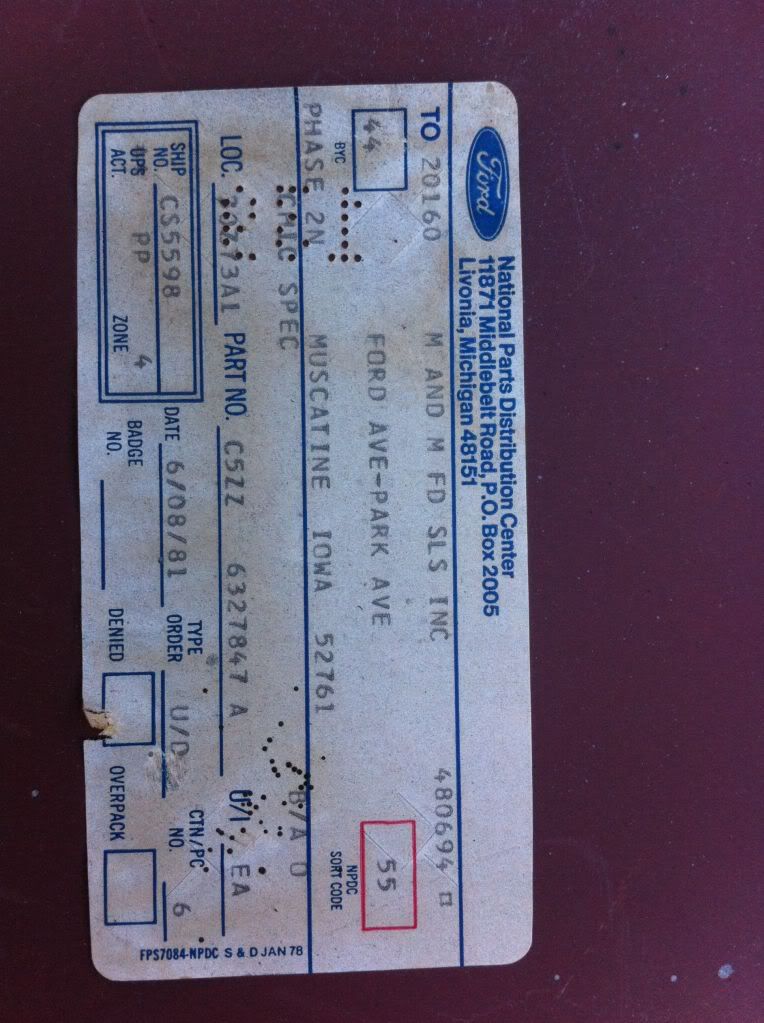

For my Mustang project, I'm lucky enough to have a pair of red oxide NOS 1/4s circa 1981.

I wanted to get the insides of my 1/4 panels painted before I put them on. Looking at the upcoming weather, I really wanted to get that done this weekend.

The red oxide had what looked like black little bumps in a couple of spots, almost like grains of sand in spots on the inside. I was wondering if maybe some rust was starting underneath the red oxide? Longs story short, I thought I should strip it off and epoxy prime, and that it would be a lot easier when they weren't on the car and I had full access.

I first started on one to remove the paint with an electric die grinder with 3" 80 grit roloc discs. That was working ok, but really wasn't good for the corners and tight spots. About an hour into it, the die grinder stopped working.

I then switched to my DA, which isn't the greatest for a concave surface, and was even worse for the inside corners. I did manage to strip all the spots with the bumps.

I got about this far:

and decided I had done just about all the spots that will be visible and were ever actually painted on the original cars. So I scuffed the rest with a scotch brite pad, and started masking off the flanges were I had already stripped and sprayed weld thru primer.

By then it was too late to paint, so that's were the project stands.

Should I get the rest off before I epoxy? If so, suggestions on how to do it appreciated.

Take a look at the pictures and keep in mind these areas will never see weather, and most most of the areas can't be seen when the car is assembled. The inside surfaces that are visible from the trunk are mostly bare steel now, except back where the tail lights go. That is a real mess of nooks and crannies. Not sure how I could get all this old paint out of there. For what it's worth, where i could get to it, the paint seems stuck to these panels remarkably well.

I wanted to get the insides of my 1/4 panels painted before I put them on. Looking at the upcoming weather, I really wanted to get that done this weekend.

The red oxide had what looked like black little bumps in a couple of spots, almost like grains of sand in spots on the inside. I was wondering if maybe some rust was starting underneath the red oxide? Longs story short, I thought I should strip it off and epoxy prime, and that it would be a lot easier when they weren't on the car and I had full access.

I first started on one to remove the paint with an electric die grinder with 3" 80 grit roloc discs. That was working ok, but really wasn't good for the corners and tight spots. About an hour into it, the die grinder stopped working.

I then switched to my DA, which isn't the greatest for a concave surface, and was even worse for the inside corners. I did manage to strip all the spots with the bumps.

I got about this far:

and decided I had done just about all the spots that will be visible and were ever actually painted on the original cars. So I scuffed the rest with a scotch brite pad, and started masking off the flanges were I had already stripped and sprayed weld thru primer.

By then it was too late to paint, so that's were the project stands.

Should I get the rest off before I epoxy? If so, suggestions on how to do it appreciated.

Take a look at the pictures and keep in mind these areas will never see weather, and most most of the areas can't be seen when the car is assembled. The inside surfaces that are visible from the trunk are mostly bare steel now, except back where the tail lights go. That is a real mess of nooks and crannies. Not sure how I could get all this old paint out of there. For what it's worth, where i could get to it, the paint seems stuck to these panels remarkably well.