C

coupe

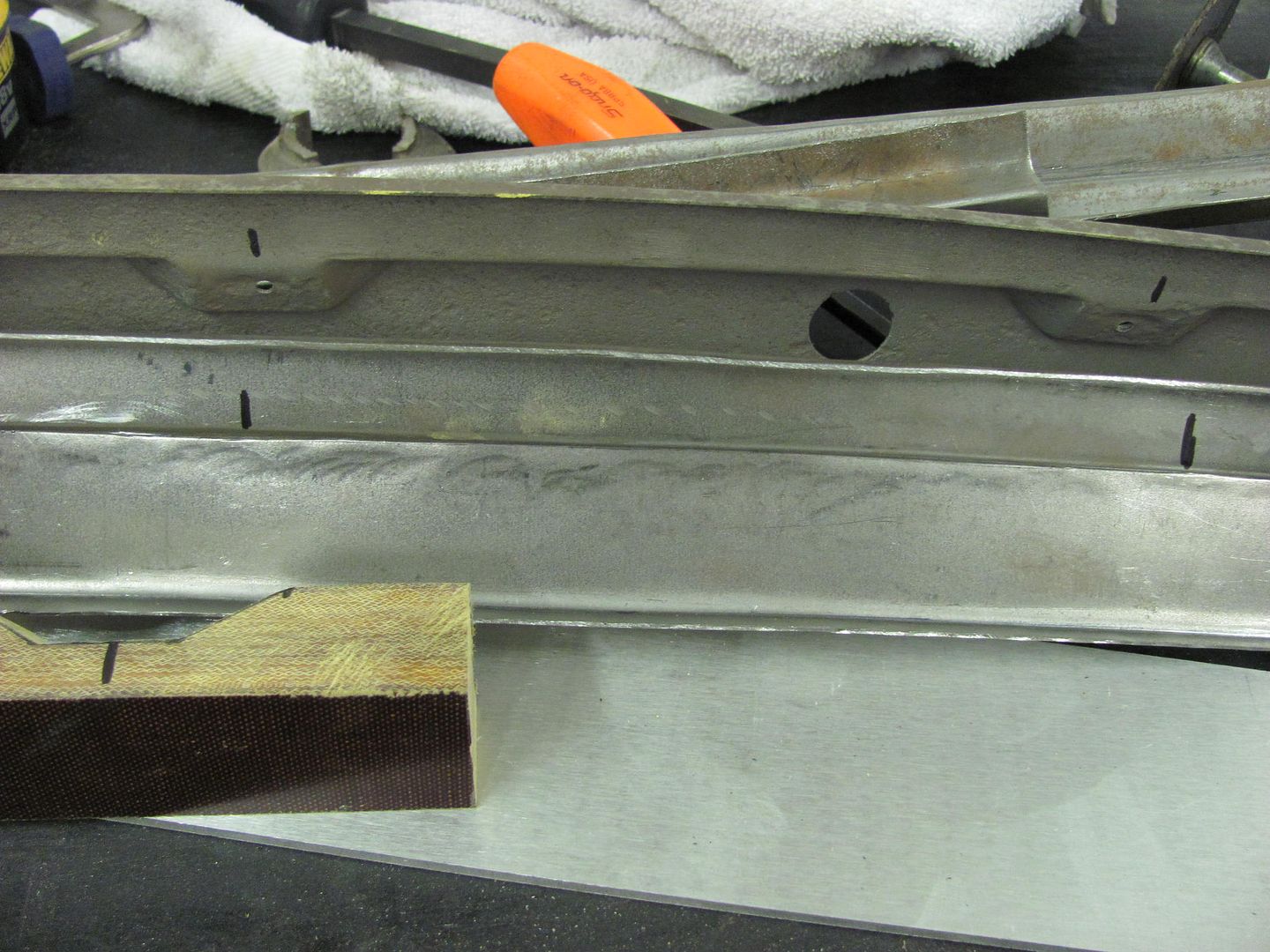

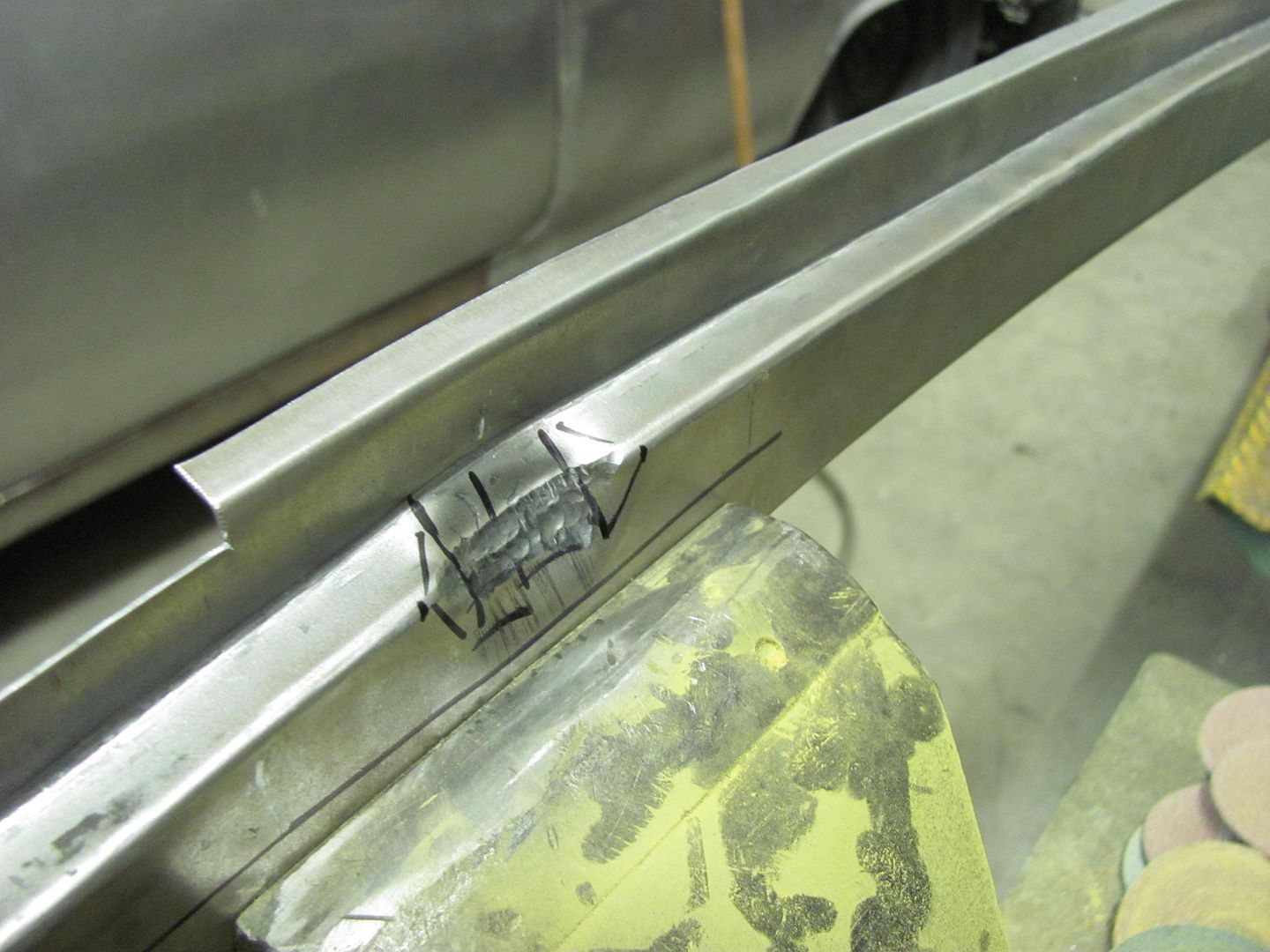

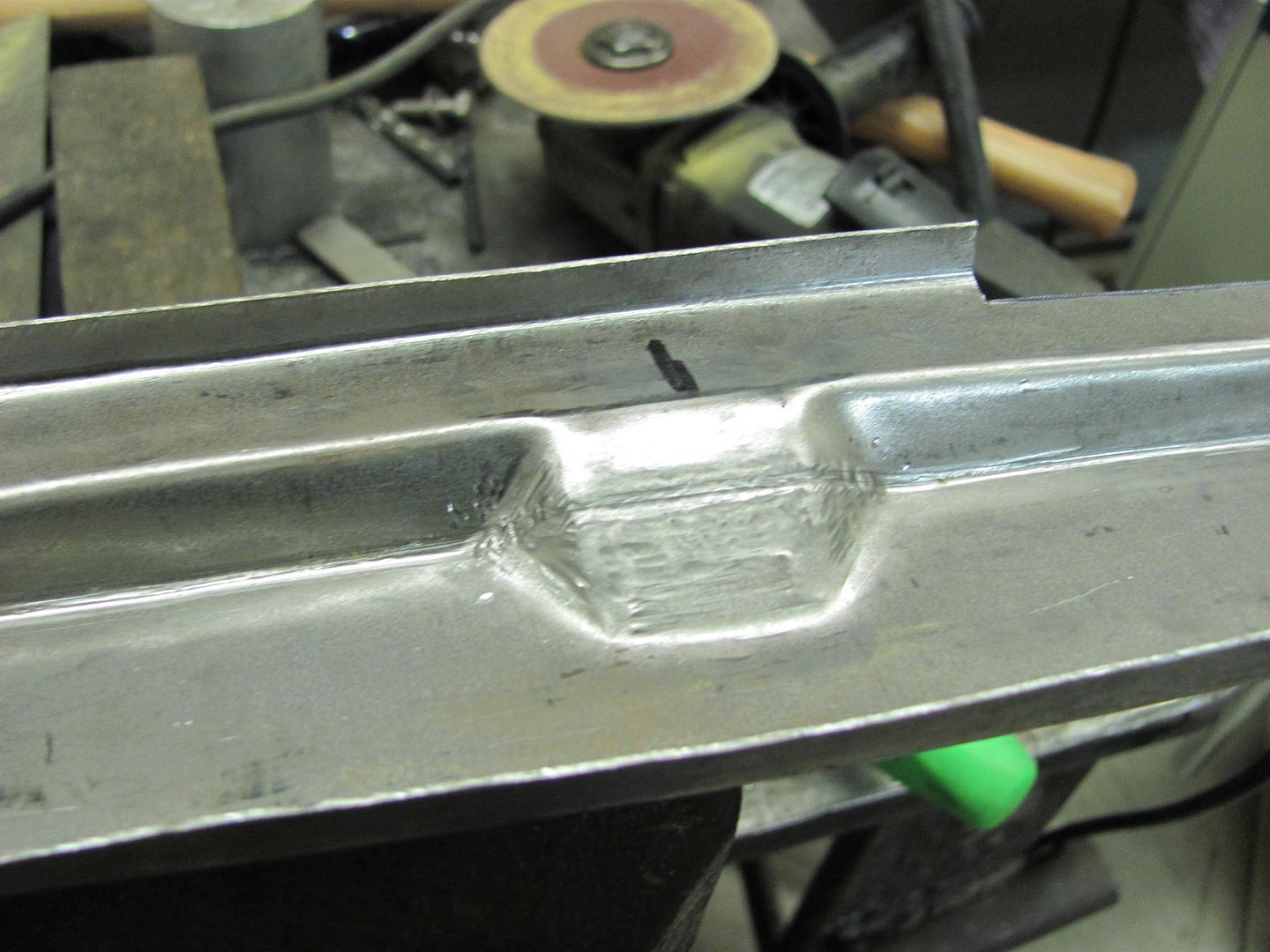

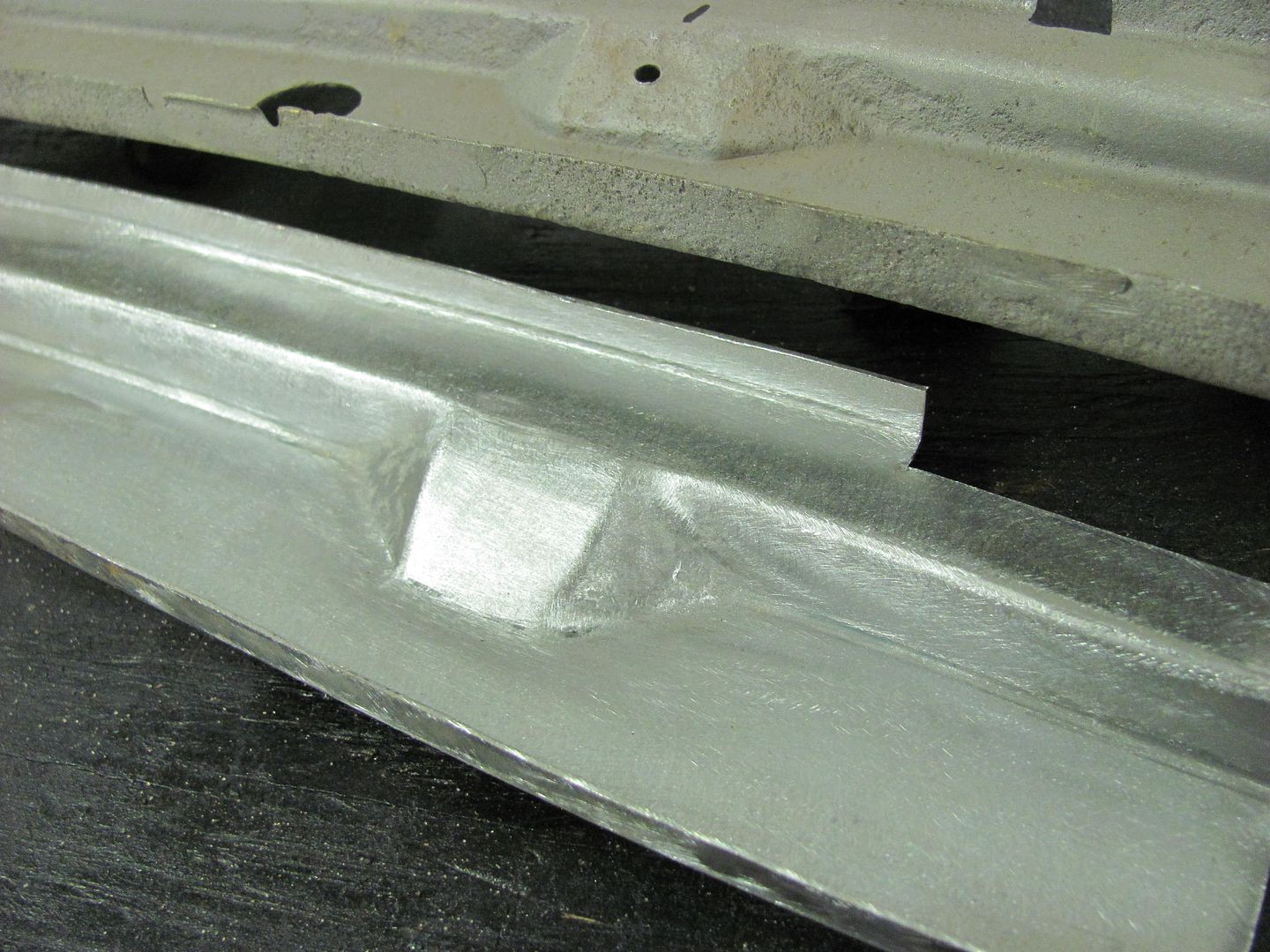

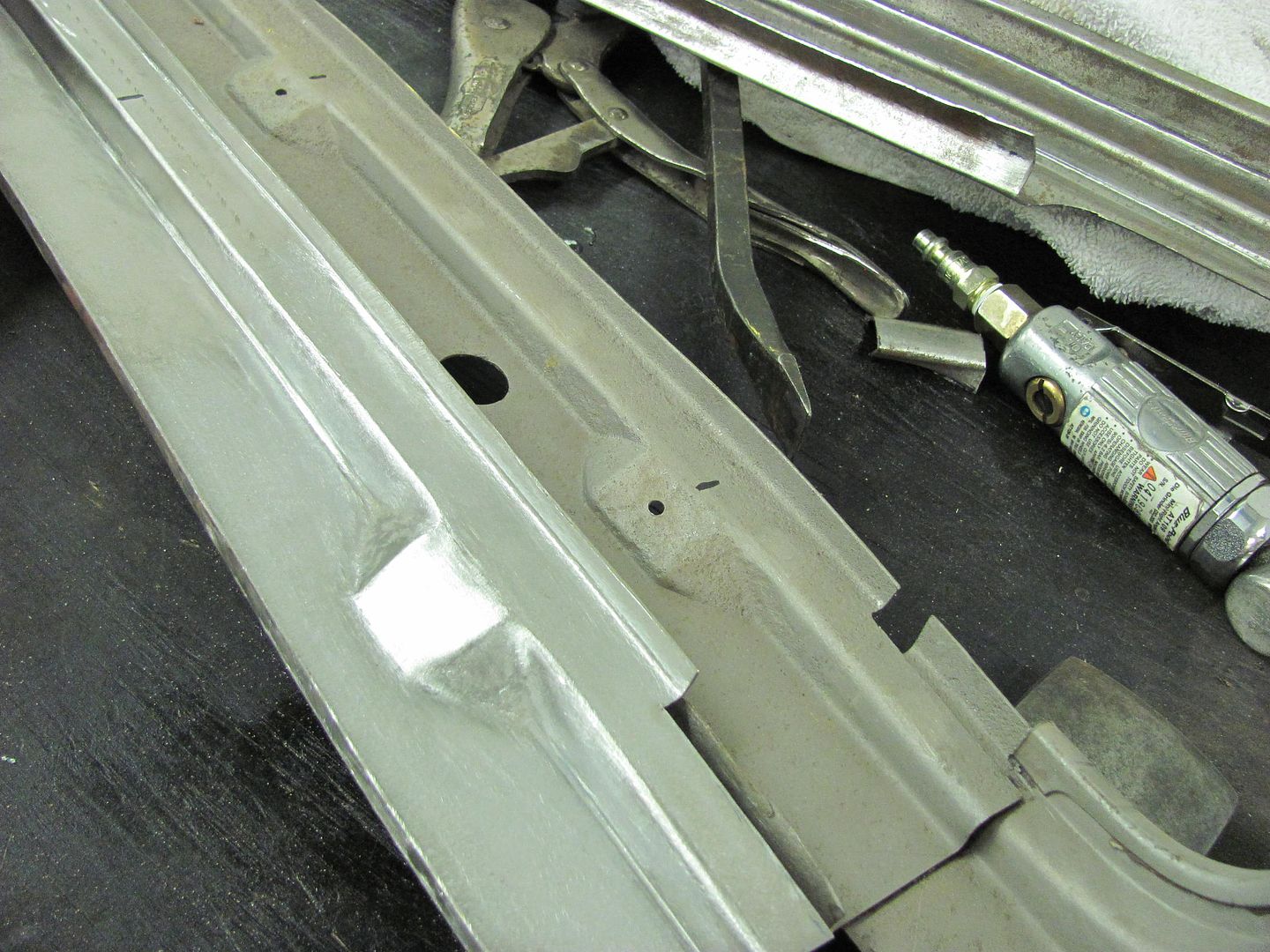

Ok so I have a set of 40 ford pickup running boards that are in less than desirable shape. Their is heavy pitting in the metal in many places between the ribs, for those of you who are familiar with forty's you know exactly what I'm referring to. Any way I am considering priming and blocking them say, three times and I feel that will eliminate 90 percent of the trouble pitting areas. I know the standard 2k will easily fill and take care of these areas but have heard a lot of people comment on epoxy being the more stable product and having better results with dry down or sand scratch swelling after a few turns in the summer heat. Would like to know if any one has had much success with using epoxy in a heavy build situation and the results you were able to obtain over the duration. every one knows restorations, street rods and the like never see the weather abuse that are daily drivers do but usually fit and finish is heavily scrutinized. thanks for your input.