Machspeed

Member

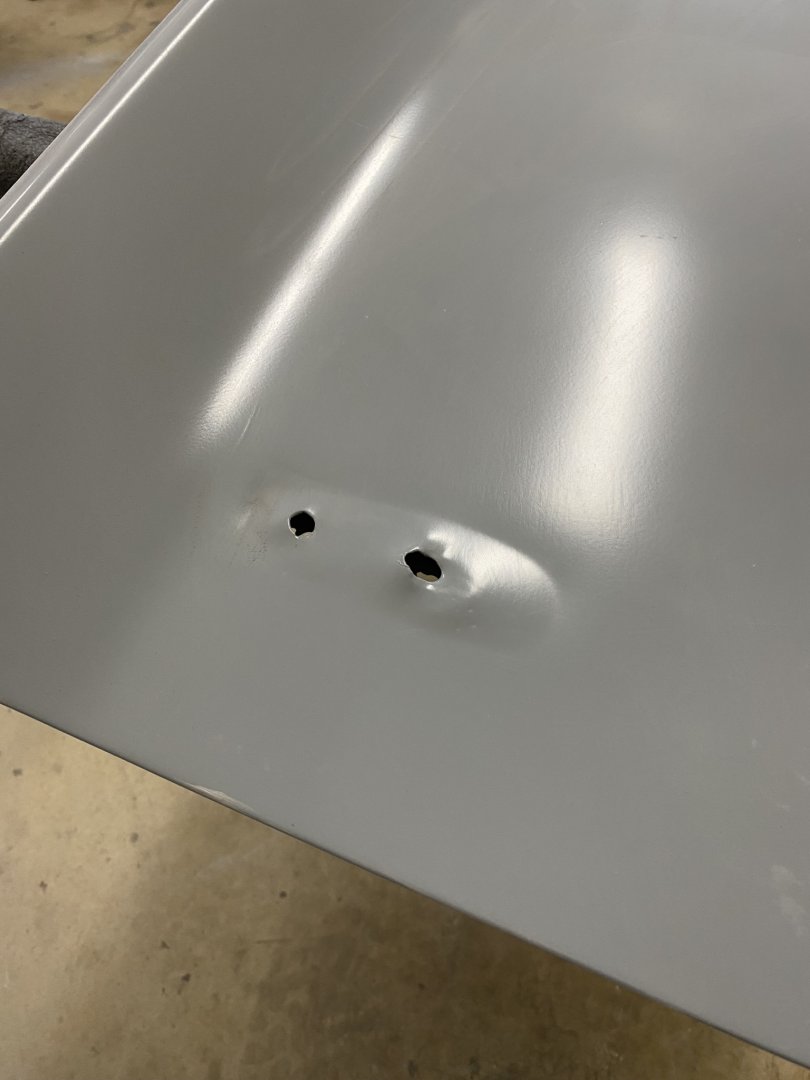

Hey friends, I've got a trunk lid and a roof that I need to do some metal work to and I'm just not sure how to approach it. The trunk lid had a rear spoiler and the roof had rear window louvers. At the attachment points (see photos) you can see where the metal is pulled up and the surrounding base of the mounting points where the louver hinges and spoiler bracket were is sunken in. I cannot get behind it, as there is supporting panel there with about 1/4" of space between the two panels. Suggestions on addressing these areas?