R

Richard Jennings

I just picked up my dipped front clip parts where they suggest to wash with warm water and Dawn soap. I believe I should sand the bare metal with 80 grit then clean with Dawn and water again, then do a final wipe with SPI 700 W&G before spraying SPI epoxy. I've sprayed SPI epoxy once when I blasted my '55 body. Thoughts ? I've never sprayed over "dipped" metal before.

Since epoxy spraying my '55 body, I've built a home hobby spray booth. Its 12'x24' insulated, drywall and floor sealed, 170 fc of LED lighting. I will pull heat into the booth through a 25"x75"x2" filter door and exit via a 18" louver fan that's 3 speed 1800/ 2000 / 2300 rpm, from my forced air Reznor furnace from my 30x48 shop.

My 30x48x10 hobby shop.....

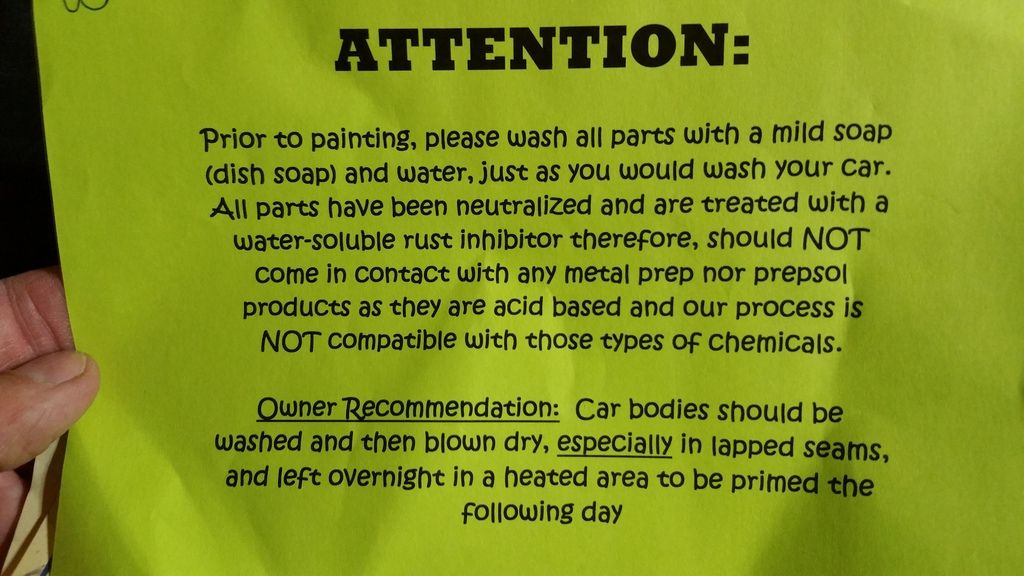

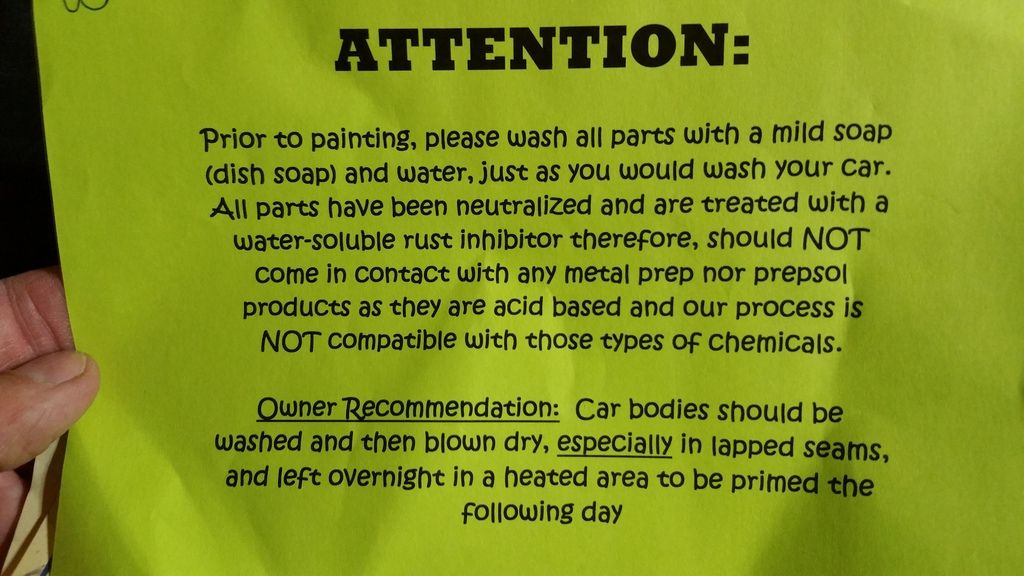

Note from the dipper......

dipped parts....

Underside of '55 hood...

My home hobby booth with 3 speed exhaust fan and louver... I big upgrade from when I first started the hobby of painting and building cars from a dirt drive way, lol....

Home hobby both opposite end filter door...

Filter door....

Since epoxy spraying my '55 body, I've built a home hobby spray booth. Its 12'x24' insulated, drywall and floor sealed, 170 fc of LED lighting. I will pull heat into the booth through a 25"x75"x2" filter door and exit via a 18" louver fan that's 3 speed 1800/ 2000 / 2300 rpm, from my forced air Reznor furnace from my 30x48 shop.

My 30x48x10 hobby shop.....

Note from the dipper......

dipped parts....

Underside of '55 hood...

My home hobby booth with 3 speed exhaust fan and louver... I big upgrade from when I first started the hobby of painting and building cars from a dirt drive way, lol....

Home hobby both opposite end filter door...

Filter door....