M

MORE IMPATIENT

So now that we are coming into the colder months and I've been loving use the reduced epoxy as a sealer for the entire summer and early fall. I have some concerns with the colder weather.

I am nearly ready to lay paint on a 54 Chevy restoration, the cab has been shot with epoxy, topped with 2 coats of urethane and blocked down a few weeks ago when it was in the mid 70's. There is no bare metal showing after block and prep so its ready to go. My concern is now the average temperature is in the 50's, low 60's and sometimes colder. There are some days where it pops back up into the 70's but that wont last much longer once we get into December and even if it does there's no guarantee I'm not working my other job that day to where I could spray this truck. I have no heated make up unit in my booth. When I am doing anything into epoxy primer I bring a small heater into the booth and heat the metal up, shoot the primer, let all the fumes evacuate for a bit than turn the heater on to keep the metal really warm for a few hours cause the booth heats up real easily, usually bring the part inside the house or put it in the sun if I run out of heater fuel since I know per the tech sheet the metal needs to be kept at least 65 degrees for the epoxy to work correctly, and reheat the next day for a few hours if the temp got to low that day.

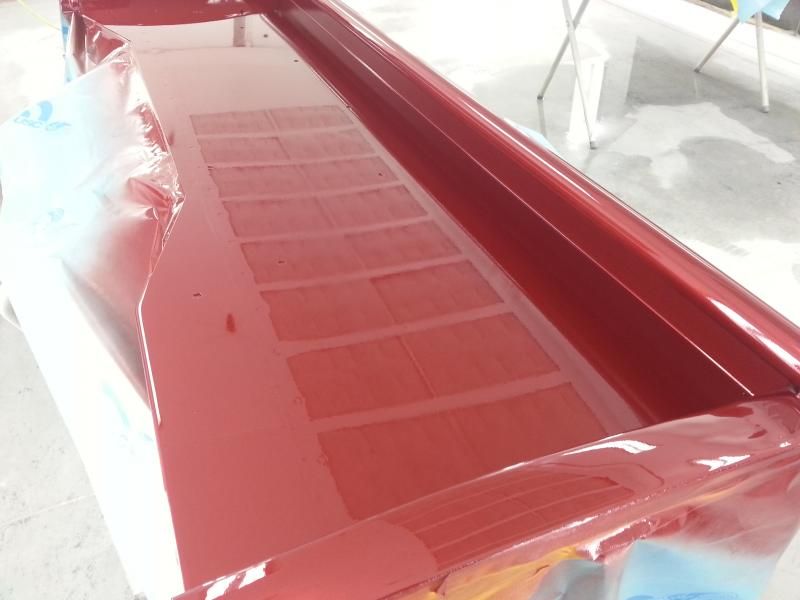

My main concern is will I have an adhesion problems spraying in colder temperatures using the reduced epoxy as a sealer if I'm not able to keep it at 65 or higher for an extended period of time ? like I stated the cab has already been epoxied, covered in urethane than guide coated and blocked down. I'm nearly ready to shoot this cab and want to avoid any potential pitfalls. Last winter I was using the spi 2k high build urethane primer and sealer and had tons of soak up issues. Ever since switching to initial primer with epoxy, covering with urethane and using reduced epoxy as a sealer I have had zero recurrences and I am very happy with that result and the product. Just want to make sure I stay on the right track. Now that were coming into winter I'm a little worried about what will happen. This is a high metallic darker burgundy color so obviously any soak up or flaws will be highly visible. I really don't want to go back to shooting urethane sealer if I can stick with the epoxy because I have just had much better results using the epoxy, but if the cold is going to be an issue that I guess I don't really have much choice in the matter.

Any input will be highly appreciated. Thanks a lot.

I am nearly ready to lay paint on a 54 Chevy restoration, the cab has been shot with epoxy, topped with 2 coats of urethane and blocked down a few weeks ago when it was in the mid 70's. There is no bare metal showing after block and prep so its ready to go. My concern is now the average temperature is in the 50's, low 60's and sometimes colder. There are some days where it pops back up into the 70's but that wont last much longer once we get into December and even if it does there's no guarantee I'm not working my other job that day to where I could spray this truck. I have no heated make up unit in my booth. When I am doing anything into epoxy primer I bring a small heater into the booth and heat the metal up, shoot the primer, let all the fumes evacuate for a bit than turn the heater on to keep the metal really warm for a few hours cause the booth heats up real easily, usually bring the part inside the house or put it in the sun if I run out of heater fuel since I know per the tech sheet the metal needs to be kept at least 65 degrees for the epoxy to work correctly, and reheat the next day for a few hours if the temp got to low that day.

My main concern is will I have an adhesion problems spraying in colder temperatures using the reduced epoxy as a sealer if I'm not able to keep it at 65 or higher for an extended period of time ? like I stated the cab has already been epoxied, covered in urethane than guide coated and blocked down. I'm nearly ready to shoot this cab and want to avoid any potential pitfalls. Last winter I was using the spi 2k high build urethane primer and sealer and had tons of soak up issues. Ever since switching to initial primer with epoxy, covering with urethane and using reduced epoxy as a sealer I have had zero recurrences and I am very happy with that result and the product. Just want to make sure I stay on the right track. Now that were coming into winter I'm a little worried about what will happen. This is a high metallic darker burgundy color so obviously any soak up or flaws will be highly visible. I really don't want to go back to shooting urethane sealer if I can stick with the epoxy because I have just had much better results using the epoxy, but if the cold is going to be an issue that I guess I don't really have much choice in the matter.

Any input will be highly appreciated. Thanks a lot.