rustover

Member

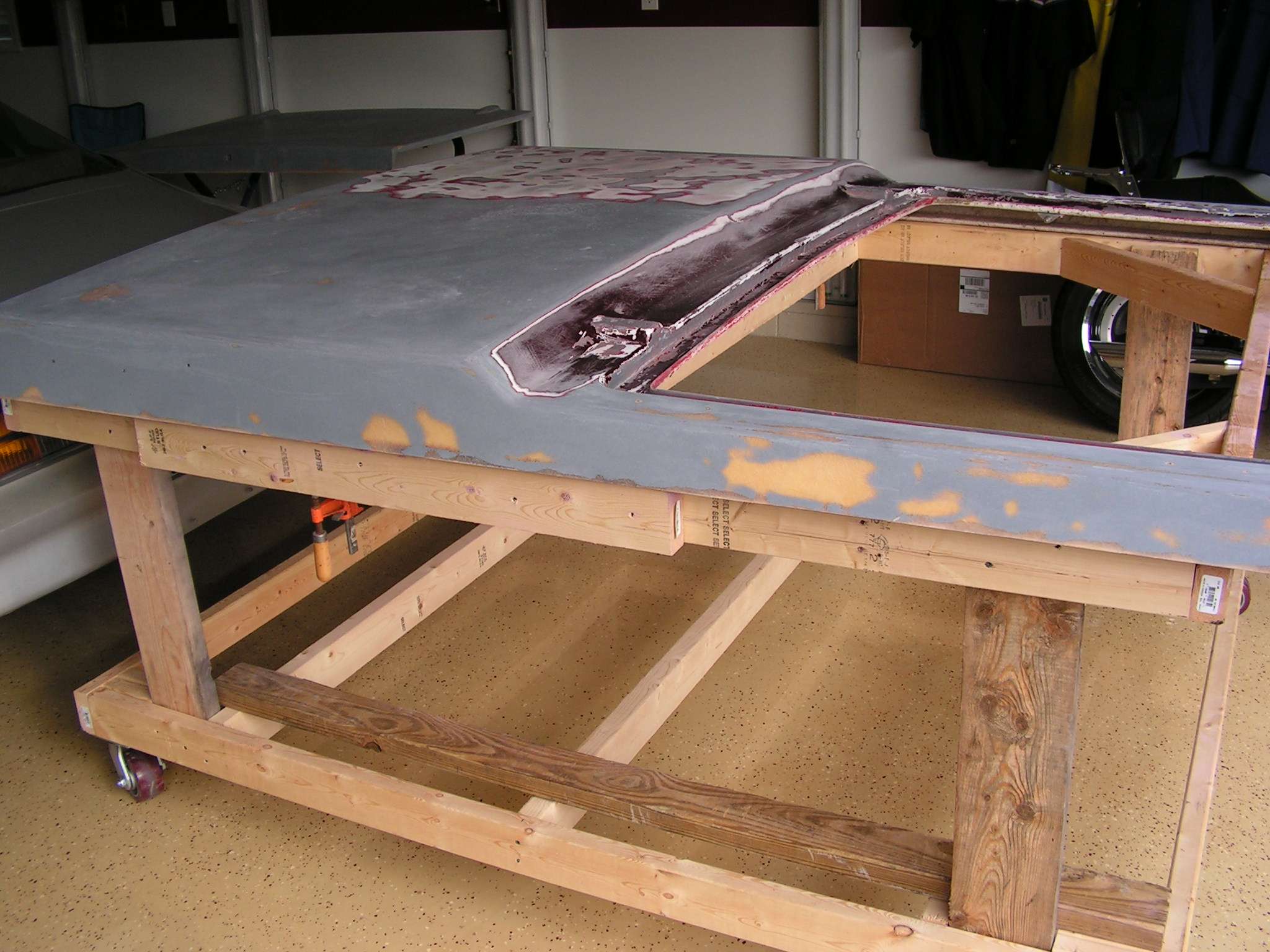

The clear is flaking on the bed cover of my Silverado. I have built a homemade dolly for it and I want to strip it and re-spray it.

I took a da to one small section using 80 grit paper. Here is what I have, clear, base of my truck, grey primer (maybe a sealer), a white coating, and two red coatings, then I hit the grey fiberglass. When I removed the weather stripping it was red underneath. I'm guessing it was red at one time. I'm not sure what the white coating is. It seems to be thick. One thing I noticed is that I can't use the da on the rounded edges because I will groove the fiberglass.

I want to strip this thing down, I'm thinking I should go all the way to the grey. On the rounded edges and around the hinge bosses I will have to use the fiberglass stripper. I will probably use the stripper first, then da the flat areas.

Once stripped, I will start with 2 coats of epoxy, followed by 2-3 coats of polyester primer (this thing waves at everybody), block sand then sealer, base/clear.

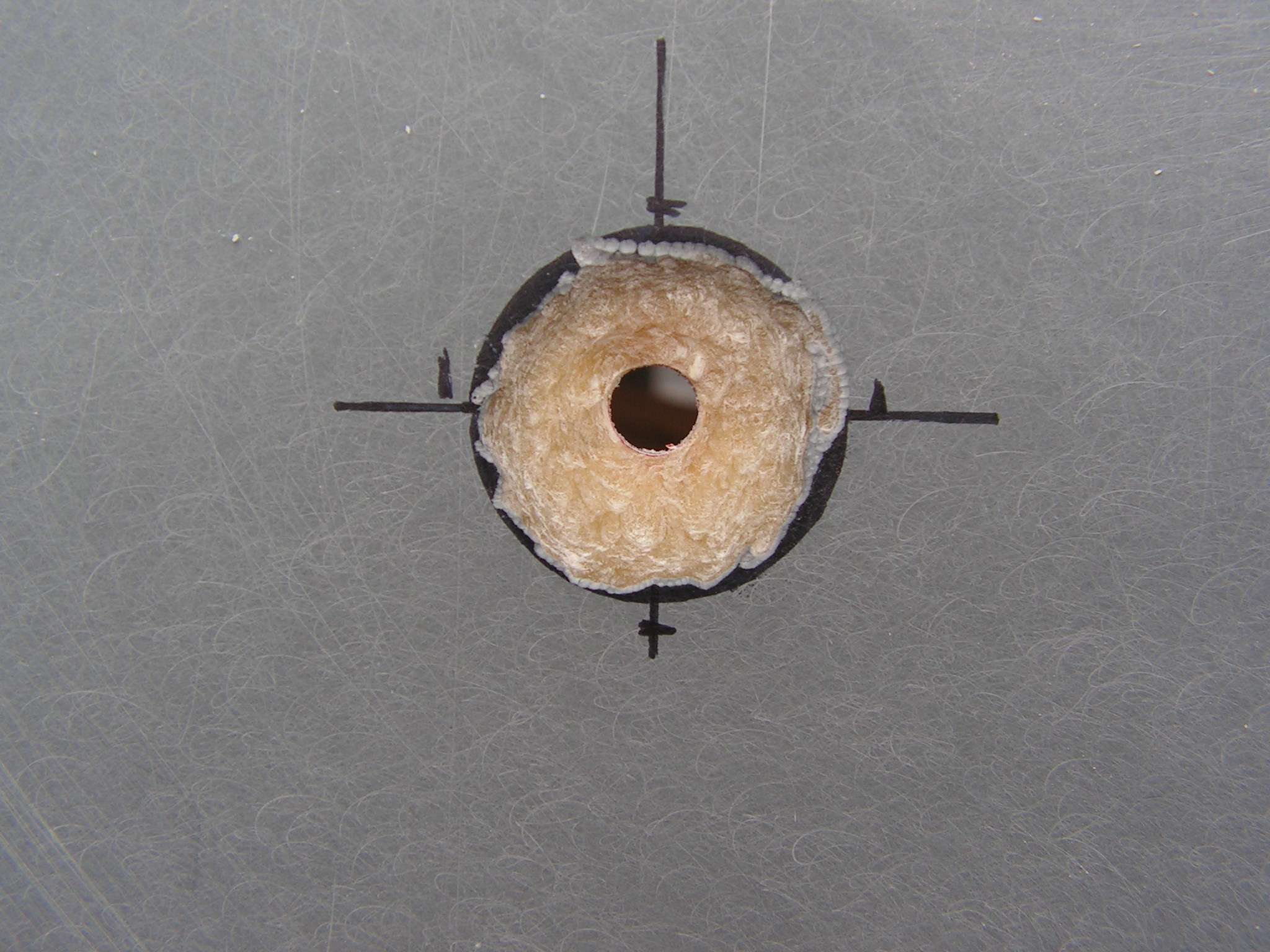

What do you guys think? Do you think 80 grit is too coarse? What the best way of neutralizing the stripper on fiberglass? There is also some holes that I want to fill because I'm going with a different set of emblems. What do you recommend to do this?

Thanks for the help in advance. I know I will have more questions as I get started. This is going to be a great project for me to get my feet wet with a spray gun. Thanks, Russ

I took a da to one small section using 80 grit paper. Here is what I have, clear, base of my truck, grey primer (maybe a sealer), a white coating, and two red coatings, then I hit the grey fiberglass. When I removed the weather stripping it was red underneath. I'm guessing it was red at one time. I'm not sure what the white coating is. It seems to be thick. One thing I noticed is that I can't use the da on the rounded edges because I will groove the fiberglass.

I want to strip this thing down, I'm thinking I should go all the way to the grey. On the rounded edges and around the hinge bosses I will have to use the fiberglass stripper. I will probably use the stripper first, then da the flat areas.

Once stripped, I will start with 2 coats of epoxy, followed by 2-3 coats of polyester primer (this thing waves at everybody), block sand then sealer, base/clear.

What do you guys think? Do you think 80 grit is too coarse? What the best way of neutralizing the stripper on fiberglass? There is also some holes that I want to fill because I'm going with a different set of emblems. What do you recommend to do this?

Thanks for the help in advance. I know I will have more questions as I get started. This is going to be a great project for me to get my feet wet with a spray gun. Thanks, Russ