AllGoNoShow

Promoted Users

Not sure if this is the right place for this, but I'm getting in a little over my head and could use some help. I originally planned on using SPI matte clear or their flattner but it seems that both products have been discontinued. I am repairing an outer rocker (just in the jamb area) and painting a new steering column/steering wheel to match a BC/CC job the previous owner of my C10 put on where the clear is matte with no shine.

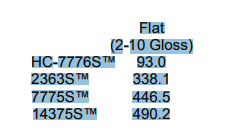

All parts are in SPI epoxy and I'm going to base right over that once its sealed. I went to a local jobber and picked up the base (Axalta Chromobase) and they sold me 4:1 Chromobase Clear, the Activator, and a "Low VOC Matting Additive" (2623S). I came home and looked at the tech sheet for the matting additive (expecting to see the ratios to mix it together with), and it is listed as "cumulative weight by pint" depending on sheen requested. For instance, for "matte" finish it says :

So I guess my question is, how do I convert this to a ratio I can use to mix? And how is the above numbers represented-is it saying to add that much of all of those components or is it saying to add 93 grams of 7776s (which is the clear), then 245grams of the 2363s (which is the matte additive)? Or is it saying to add the amount specifically listed for each of those components? (I'm assuming the former, but just want to confirm)

Also, the jobber never mentioned nor sold me the 14375S (which is a ChromoPremier "Reducer for clears and single stage paints") that apparently I need to mix in. I have some SPI Urethane Reducer I just bought- would I be able to use this instead?

I will do several test pieces to make sure this all works before I put paint on the parts, but whatever assistance you could provide would be very helpful. I'm trying to learn and figure this out before I start pulling my hair out and just say F-it and put some aerosol 2k Spray-Max Matte on it!

Nick

All parts are in SPI epoxy and I'm going to base right over that once its sealed. I went to a local jobber and picked up the base (Axalta Chromobase) and they sold me 4:1 Chromobase Clear, the Activator, and a "Low VOC Matting Additive" (2623S). I came home and looked at the tech sheet for the matting additive (expecting to see the ratios to mix it together with), and it is listed as "cumulative weight by pint" depending on sheen requested. For instance, for "matte" finish it says :

So I guess my question is, how do I convert this to a ratio I can use to mix? And how is the above numbers represented-is it saying to add that much of all of those components or is it saying to add 93 grams of 7776s (which is the clear), then 245grams of the 2363s (which is the matte additive)? Or is it saying to add the amount specifically listed for each of those components? (I'm assuming the former, but just want to confirm)

Also, the jobber never mentioned nor sold me the 14375S (which is a ChromoPremier "Reducer for clears and single stage paints") that apparently I need to mix in. I have some SPI Urethane Reducer I just bought- would I be able to use this instead?

I will do several test pieces to make sure this all works before I put paint on the parts, but whatever assistance you could provide would be very helpful. I'm trying to learn and figure this out before I start pulling my hair out and just say F-it and put some aerosol 2k Spray-Max Matte on it!

Nick