95maxrider

Promoted Users

I've done two other repair jobs to my cars in the past, but that was with 2k rattle cans mixed up at the local paint supply store. This project was my first using my new air compressor and real paint gun setup in my home garage, so there was a lot of learning going on. Lots of mistakes too! This Acura TL is my mom's car, and since she doesn't exactly have an eye for paint perfection, I figured it would be a great project for me to get comfortable with all of my new tools and supplies.

My mom had backed into something at one point, and then my step dad backed his trailer into the same panel, so I decided to repair the PS rear quarter panel.

I ground it down to bare metal and got busy with my new stud welder/puller.

This went well enough, but there were a couple spots where I created some holes in the body when pulling out the stud, so those would eventually be filled with some fiberglass filler. I couldn't figure out if a quick one second weld versus a longer 2 second weld made it more or less likely that I would create a hole when pulling. I eventually decided to just do fewer pulls on each stud, and stopped trying to twist them off and just grind them smooth when I was done to reduce the chances of making holes.

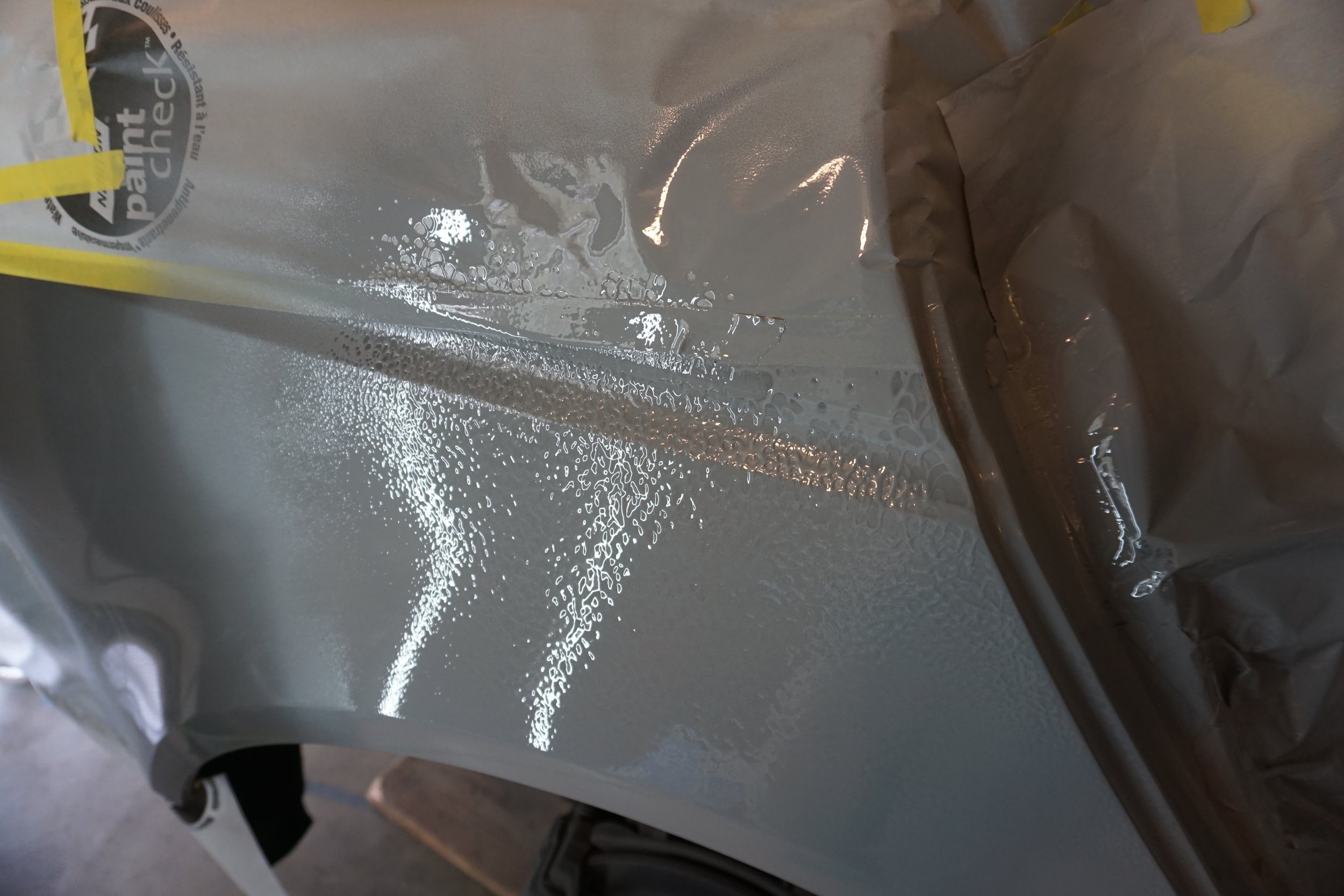

Next up was my first use of a paint gun and SPI epoxy. I'm using an LPH400 with the orange 1.3 setup. I went a little heavy with this application:

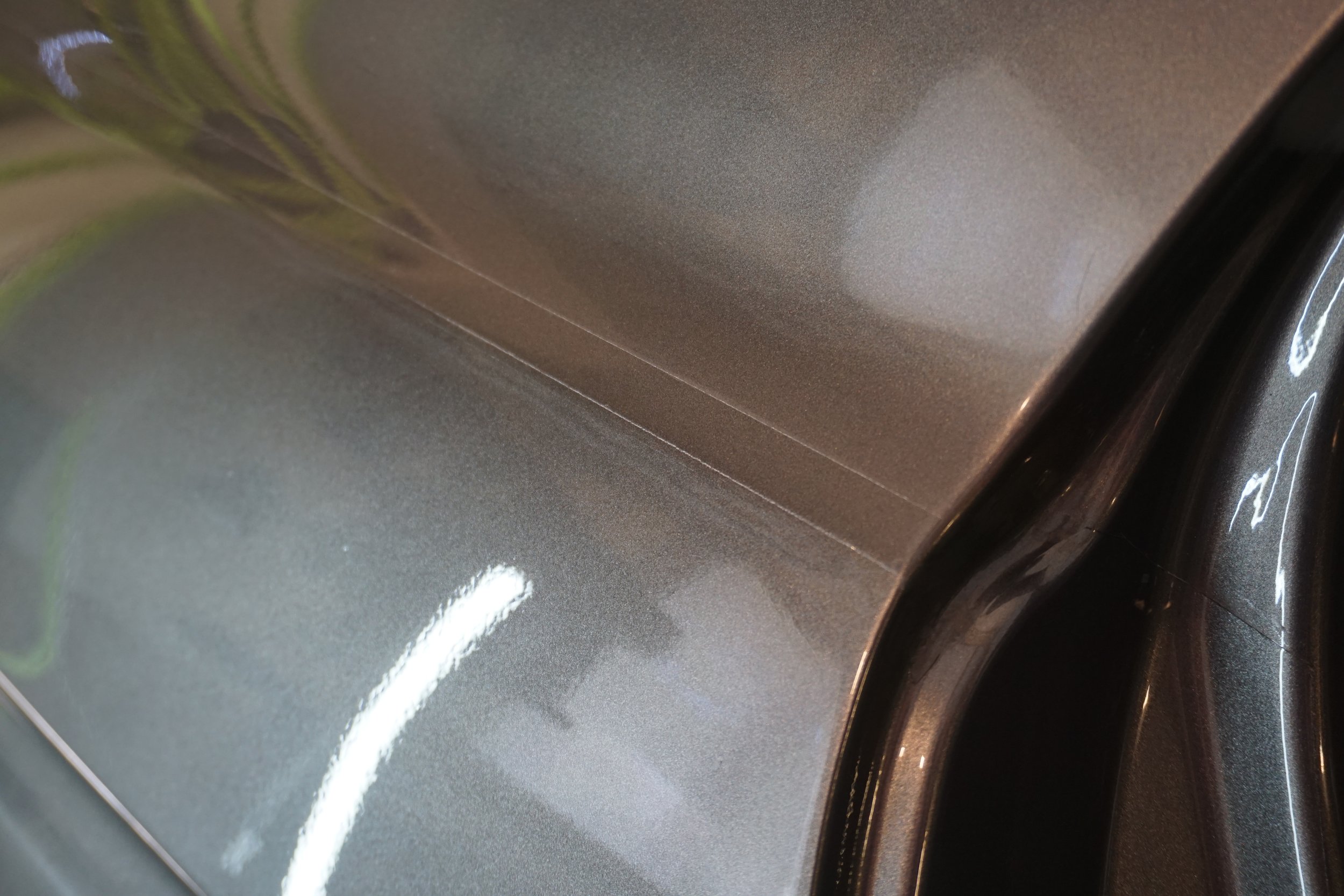

Then on to the 3M Platinum filler. This was a very tedious process since there were so many high spots from the stud puller, as well as the high spots created from the initial accident. Had to hammer those down as they showed up. It didn't help that this area has very few flat areas; there was a curve to almost everything which made things really challenging. I probably spent a full day on this. I used my new Black Diamond blocks (made by Dean here on the forums) where I could, but even the smaller block was too large and hard for much of the panel and I had to use a very flexible pad for the curved areas.

My mom had backed into something at one point, and then my step dad backed his trailer into the same panel, so I decided to repair the PS rear quarter panel.

I ground it down to bare metal and got busy with my new stud welder/puller.

This went well enough, but there were a couple spots where I created some holes in the body when pulling out the stud, so those would eventually be filled with some fiberglass filler. I couldn't figure out if a quick one second weld versus a longer 2 second weld made it more or less likely that I would create a hole when pulling. I eventually decided to just do fewer pulls on each stud, and stopped trying to twist them off and just grind them smooth when I was done to reduce the chances of making holes.

Next up was my first use of a paint gun and SPI epoxy. I'm using an LPH400 with the orange 1.3 setup. I went a little heavy with this application:

Then on to the 3M Platinum filler. This was a very tedious process since there were so many high spots from the stud puller, as well as the high spots created from the initial accident. Had to hammer those down as they showed up. It didn't help that this area has very few flat areas; there was a curve to almost everything which made things really challenging. I probably spent a full day on this. I used my new Black Diamond blocks (made by Dean here on the forums) where I could, but even the smaller block was too large and hard for much of the panel and I had to use a very flexible pad for the curved areas.