95maxrider

Promoted Users

A few years ago I did a very amateur attempt at "rust repair" on the rear quarter panel of my 1998 BMW M3. Well, that work had started to fail and rust bubbles were popping through. Long before I purchased the car in 2015 it had been t-boned and poorly repaired, and these are the results of that. Here's what it looked like three years ago before I did my janky repairs:

And here's what it looked like before I started the project a month or so ago:

I knew that I was going to need fresh metal to do this properly, and thankfully since then I taught myself how to "weld" and "paint". I bought a replacement section for the outer part of the fender, but I needed something for the inner section too, so I found a car being parted out locally and went to chop out what I could.

There were some other rusty areas that I wanted to repair at the same time:

Under the DS tail light:

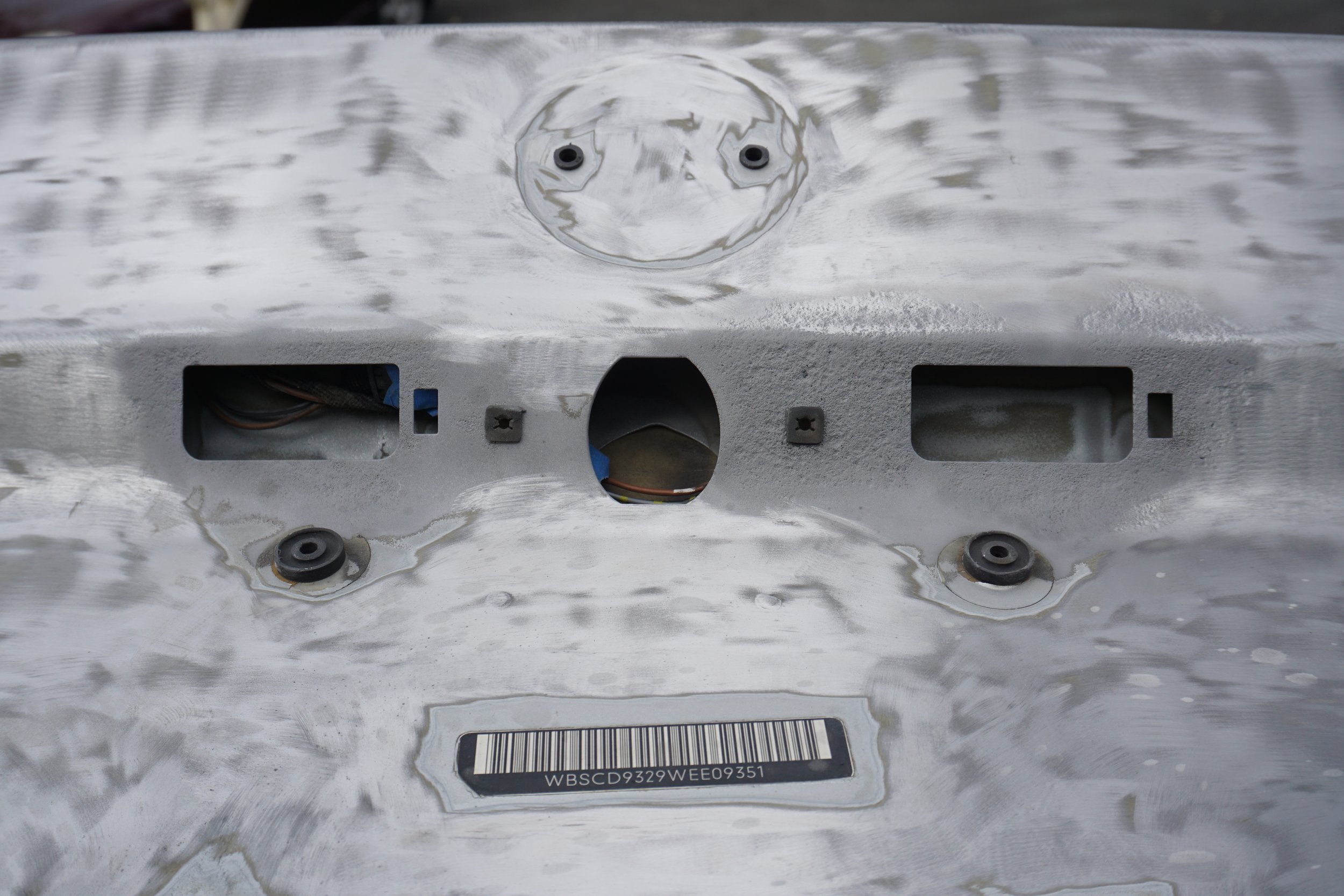

And around the trim on the trunk:

Thankfully I now also have a big media blasting tank, so I can get rid of rust correctly.

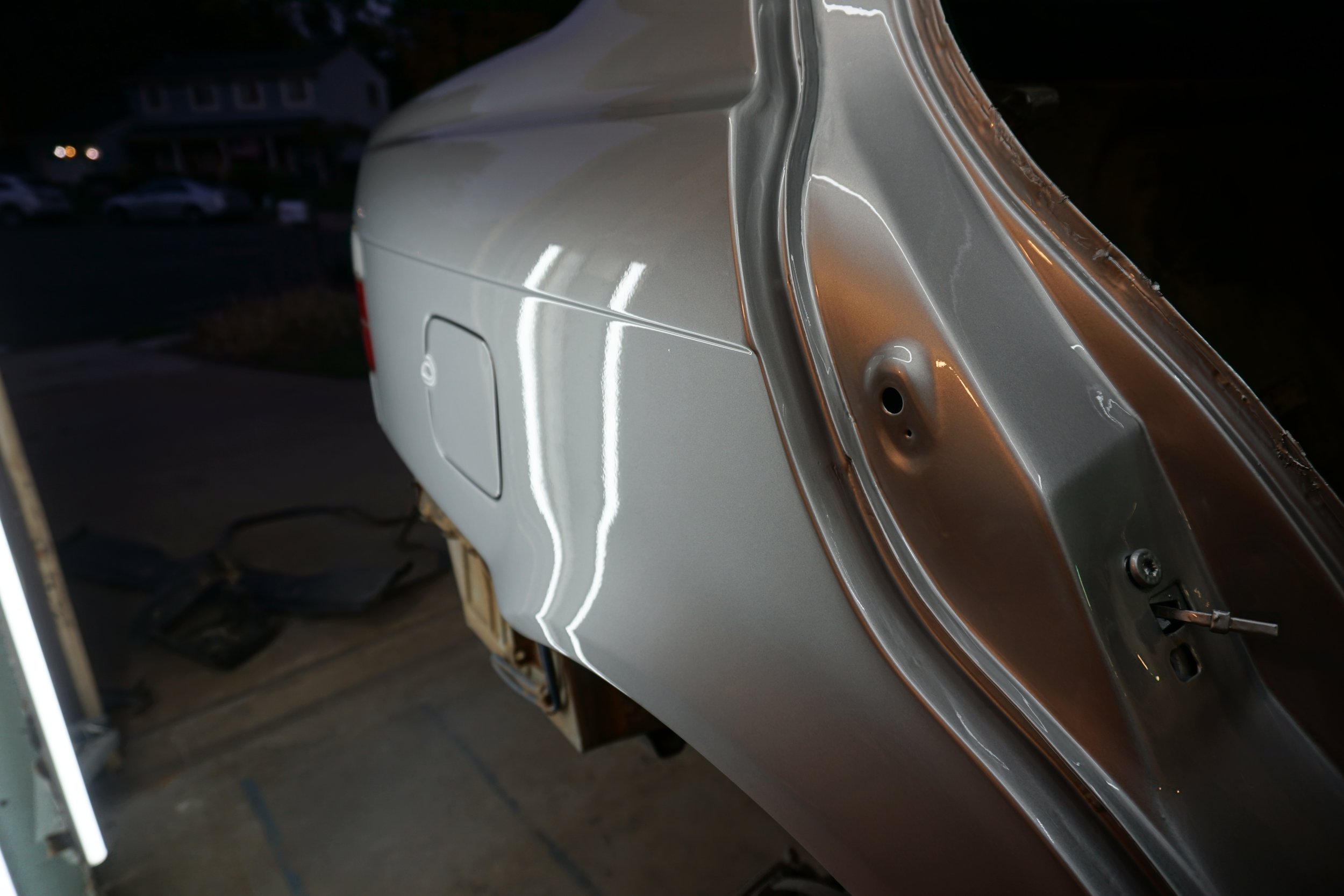

I started by taking it down to bare metal to see how far out the previous damage extended. I think I counted something like 9 layers of primer/paint on this panel! The original paint, the hack repair done before I bought the car from when it was t-boned, and then my first hack job.

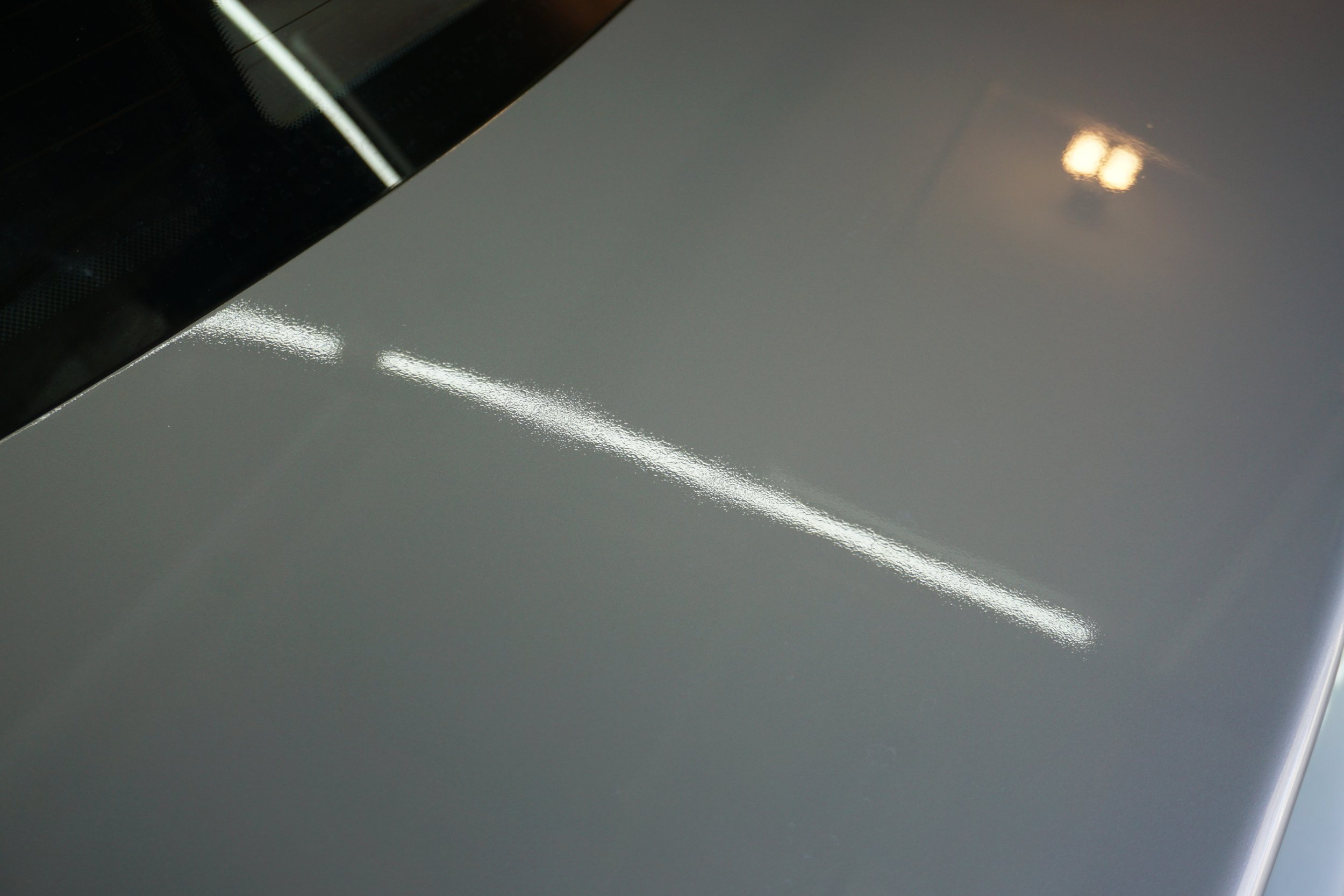

Lots of filler down here too

Oooh boy

The inside of the wheel well was all crumpled up from the accident. Welding this was going to be a real challenge.

So I started by cutting off the outer panel, and was greeted by an unholy mess on the back side of the inner panel.

I then cut out as much of the inner panel as I could, and blasted the rest with coal slag to prepare it for welding and eventual paint.

This is where I want to note that according to my measurements, this inner sheet was something like 24-25 gauge sheet metal, and the metal remaining on the car was even thinner due it parts of it having started to rust. As someone who barely knows how to weld, this presented another challenge.

I eventually got it welded up as best I could. Some of the areas that were tucked up in the body were so hard to access and the metal so thin that I just couldn't get them to weld. Not to mention I was trying to get the shape of my crumpled inner panel to match up with the one I cut from the other car. I eventually had to put my OCD aside and just accept it wasn't going to be perfect.

And here's what it looked like before I started the project a month or so ago:

I knew that I was going to need fresh metal to do this properly, and thankfully since then I taught myself how to "weld" and "paint". I bought a replacement section for the outer part of the fender, but I needed something for the inner section too, so I found a car being parted out locally and went to chop out what I could.

There were some other rusty areas that I wanted to repair at the same time:

Under the DS tail light:

And around the trim on the trunk:

Thankfully I now also have a big media blasting tank, so I can get rid of rust correctly.

I started by taking it down to bare metal to see how far out the previous damage extended. I think I counted something like 9 layers of primer/paint on this panel! The original paint, the hack repair done before I bought the car from when it was t-boned, and then my first hack job.

Lots of filler down here too

Oooh boy

The inside of the wheel well was all crumpled up from the accident. Welding this was going to be a real challenge.

So I started by cutting off the outer panel, and was greeted by an unholy mess on the back side of the inner panel.

I then cut out as much of the inner panel as I could, and blasted the rest with coal slag to prepare it for welding and eventual paint.

This is where I want to note that according to my measurements, this inner sheet was something like 24-25 gauge sheet metal, and the metal remaining on the car was even thinner due it parts of it having started to rust. As someone who barely knows how to weld, this presented another challenge.

I eventually got it welded up as best I could. Some of the areas that were tucked up in the body were so hard to access and the metal so thin that I just couldn't get them to weld. Not to mention I was trying to get the shape of my crumpled inner panel to match up with the one I cut from the other car. I eventually had to put my OCD aside and just accept it wasn't going to be perfect.