S

Skitzo

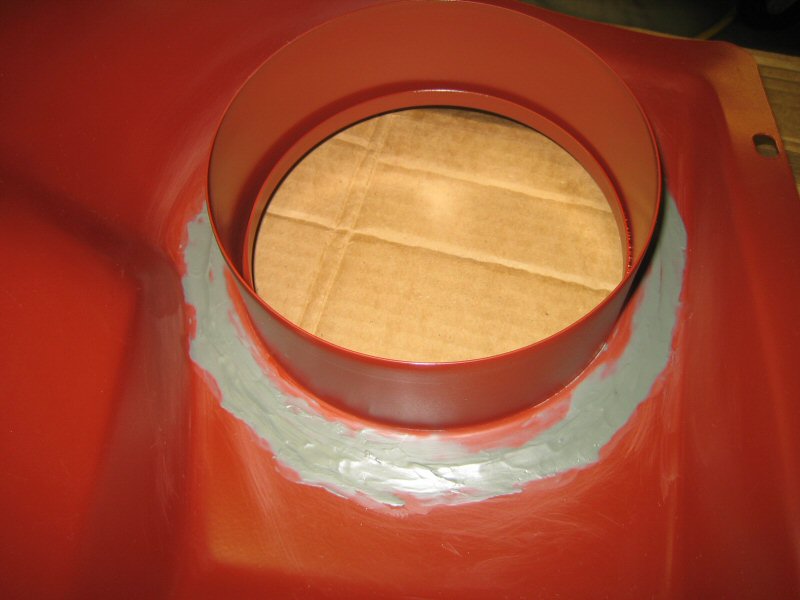

I'm working on a replacement cowl for a 65 Mustang. Typically what people do is use some seam sealer around the bases of the top-hats to seal the seam. This was my plan too. However, I kind of suck at applying seam sealer and usually make a huge mess in the process. The plan was to mask around the top hats to keep my mess contained and make it all nice and pretty - even though no one will ever see in there (yes, I'm kind of anal).

So, I masked around the outside of the base, but since it is a curve, the masking tape can't lay flat,and sort of makes wall around the top hat.

Picture:

It got me thinking... would it be a better/worse idea to mix up a batch of epoxy primer and just pour in a 1/16" layer in there, instead of using seam sealer?

Could use some input from the pros.

Thanks

So, I masked around the outside of the base, but since it is a curve, the masking tape can't lay flat,and sort of makes wall around the top hat.

Picture:

It got me thinking... would it be a better/worse idea to mix up a batch of epoxy primer and just pour in a 1/16" layer in there, instead of using seam sealer?

Could use some input from the pros.

Thanks