Craigbro63

Promoted Users

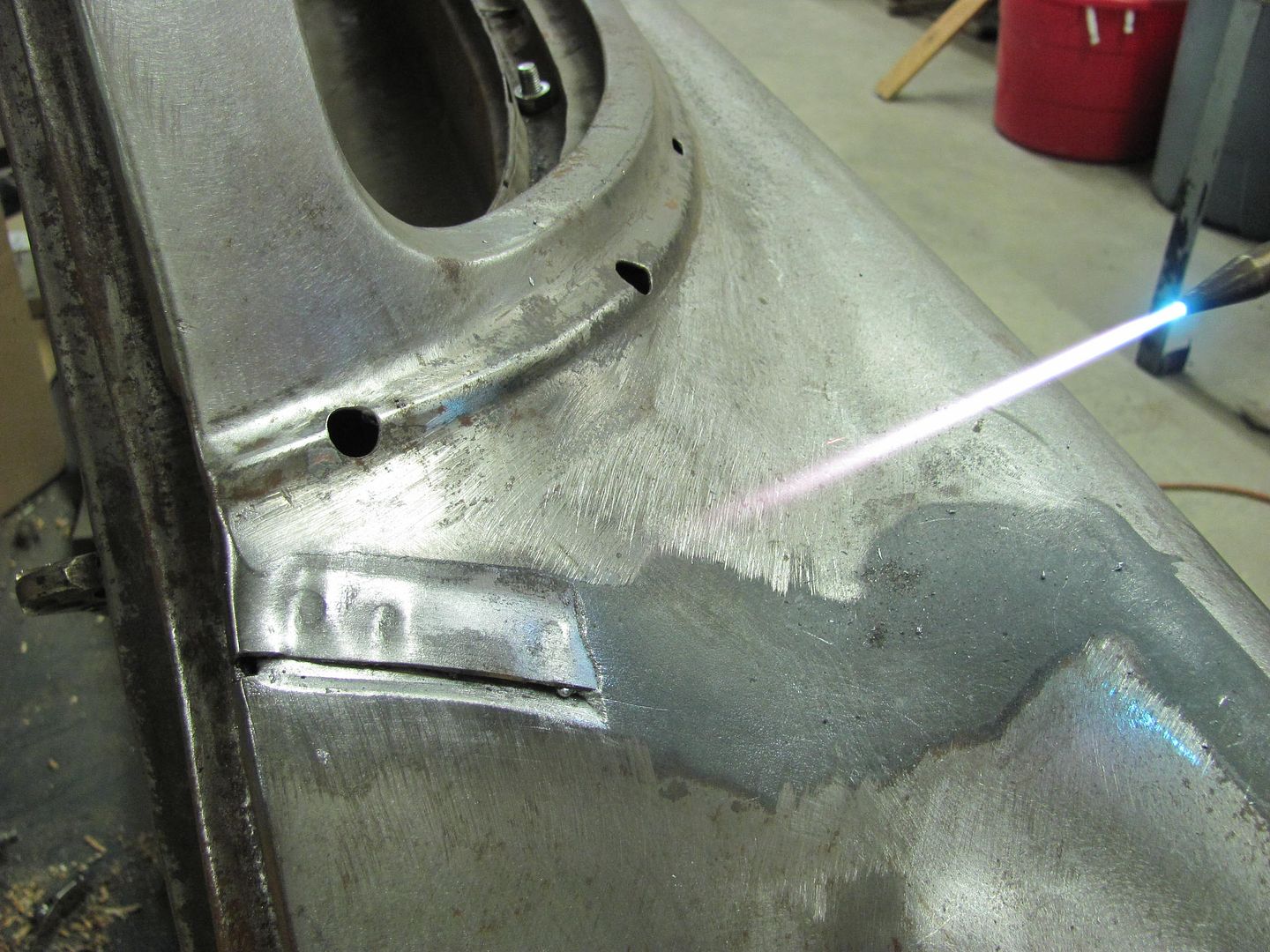

Previously there was fabric over the A Pillar and other locations, a dash pad, etc.

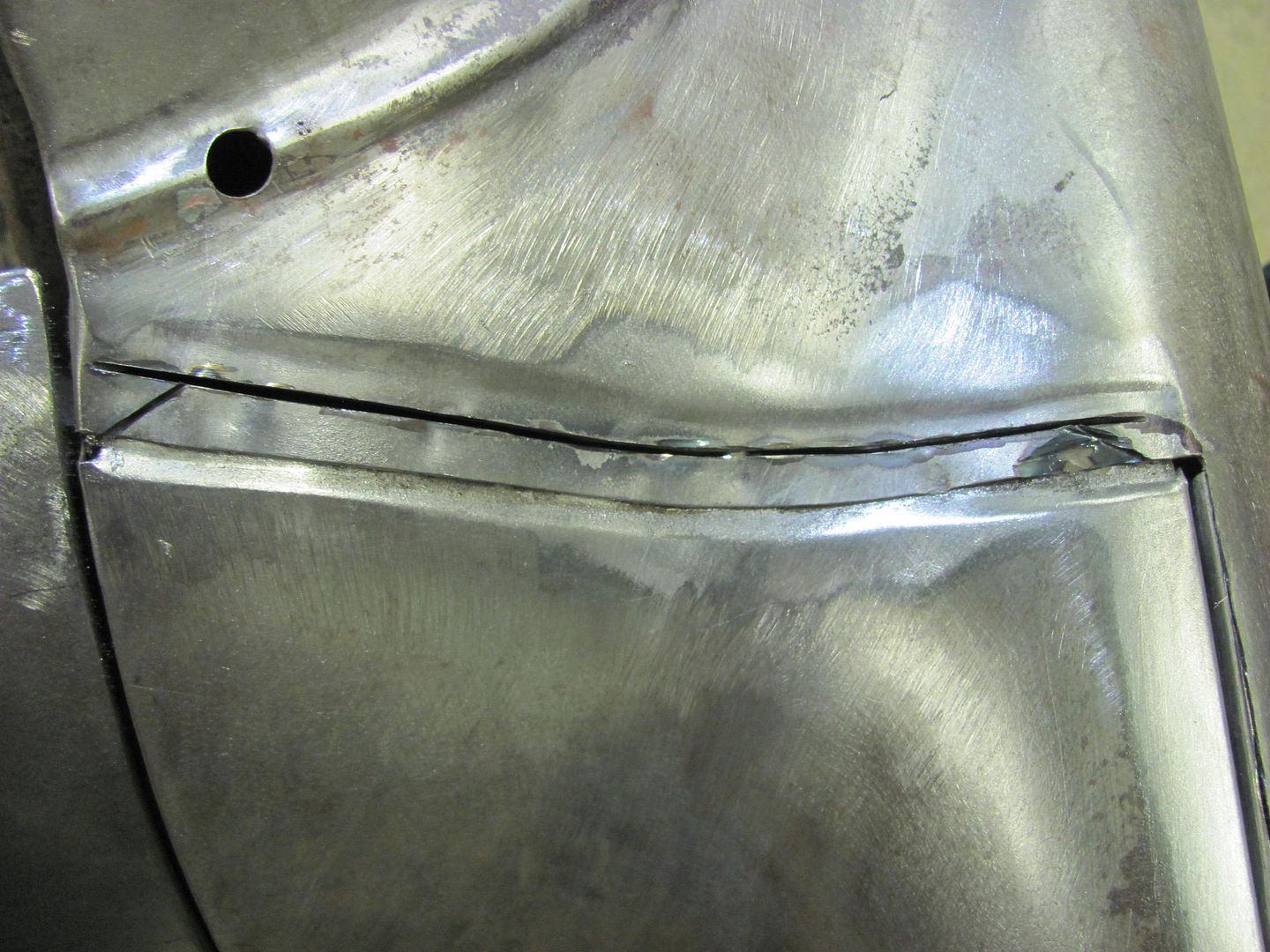

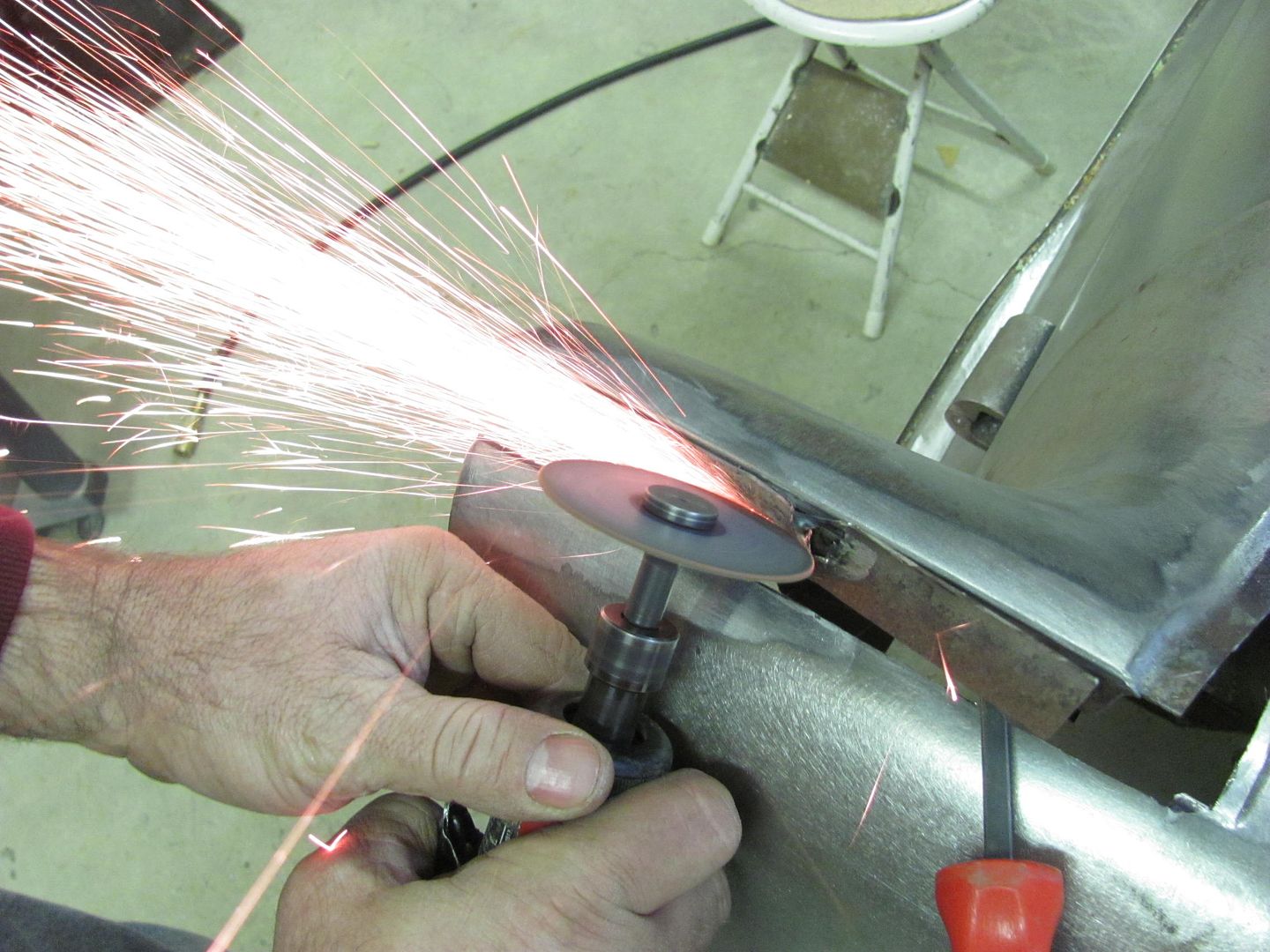

I am planning to paint these areas instead of re-fabric however there are lap seams and unfinished areas that I would like to address. I'm thinking of just leaving the lap seams as they would likely create a "hump" unless there are ways around it.

My question is should I use body filler, glazing putty, or some other product on these areas to smooth them out or how is this commonly done?

Thanks!

I am planning to paint these areas instead of re-fabric however there are lap seams and unfinished areas that I would like to address. I'm thinking of just leaving the lap seams as they would likely create a "hump" unless there are ways around it.

My question is should I use body filler, glazing putty, or some other product on these areas to smooth them out or how is this commonly done?

Thanks!