Lizer

Mad Scientist

Earlier this summer (when it was very hot) I was laying down single stage very slick.

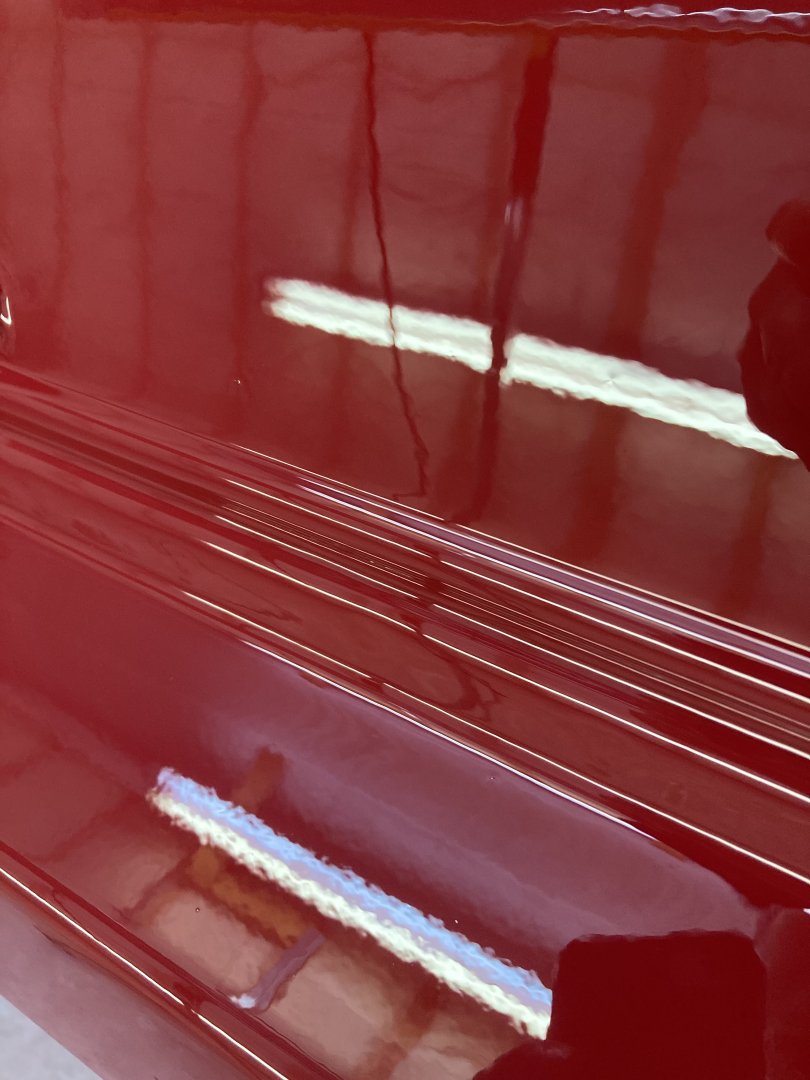

Now I’m getting more of a factory orange peel similar to what you see on late model cars now. It’s not near as slick as I used to spray it.

From an LPH400 with silver cap, I’ve been spraying 2.5-3 turns out at 35 PSI, holding it about 4 inches from the panel. With trigger to the first stop, I turn my fan in until I see the air pressure just start to bump up on my regulator. This summer I’d even sprayed as much as 4 turns out. I was moving fast but still putting it down very slick.

I’m still using the same slow hardener with my Wanda single stage that I was using this summer. So the only thing that has changed is the air temps. I was using retarder this summer as well and am not now. It was in the 80’s spraying earlier this summer and low to mid 70’s spraying now (because I’m spraying this truck in pieces as a solid red SS).

Based on these pics, what adjustments would you recommend I try?

Now I’m getting more of a factory orange peel similar to what you see on late model cars now. It’s not near as slick as I used to spray it.

From an LPH400 with silver cap, I’ve been spraying 2.5-3 turns out at 35 PSI, holding it about 4 inches from the panel. With trigger to the first stop, I turn my fan in until I see the air pressure just start to bump up on my regulator. This summer I’d even sprayed as much as 4 turns out. I was moving fast but still putting it down very slick.

I’m still using the same slow hardener with my Wanda single stage that I was using this summer. So the only thing that has changed is the air temps. I was using retarder this summer as well and am not now. It was in the 80’s spraying earlier this summer and low to mid 70’s spraying now (because I’m spraying this truck in pieces as a solid red SS).

Based on these pics, what adjustments would you recommend I try?