reallylongnickname

Promoted Users

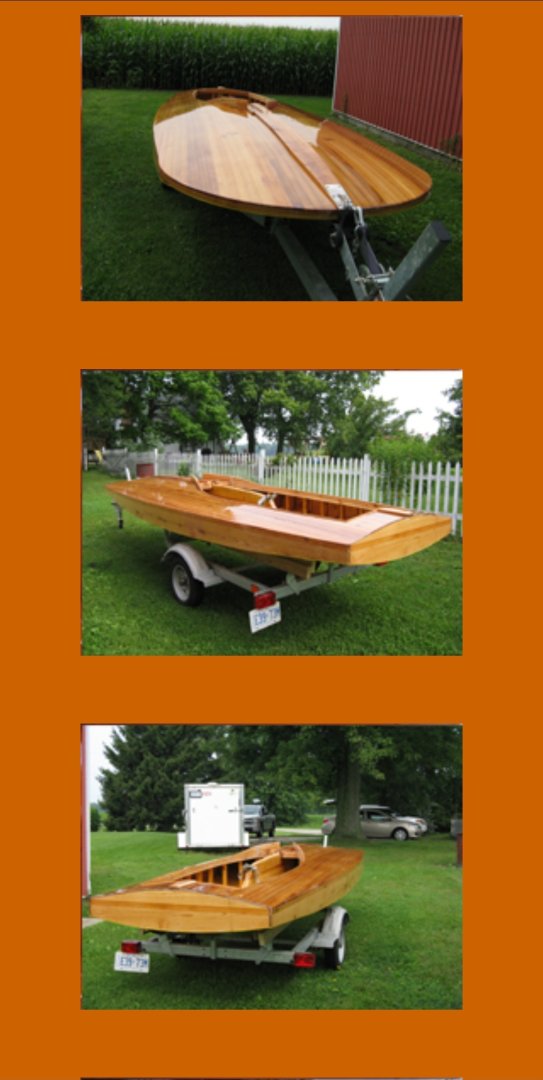

The only thing I know about this pic is that 100% sure, SPI clear was used.

Epoxy resin is normally used in river-bed table. I'm not making such a table, but I have a slab of walnut wood that I wish to make an outside table with for in a gazebo. Wondering if I could get away with spraying SPI clear and it be durable to withstand bottles, abuse etc. similar scenerio to that you'd find in a bar.

Epoxy resin is normally used in river-bed table. I'm not making such a table, but I have a slab of walnut wood that I wish to make an outside table with for in a gazebo. Wondering if I could get away with spraying SPI clear and it be durable to withstand bottles, abuse etc. similar scenerio to that you'd find in a bar.