MP&C

Member

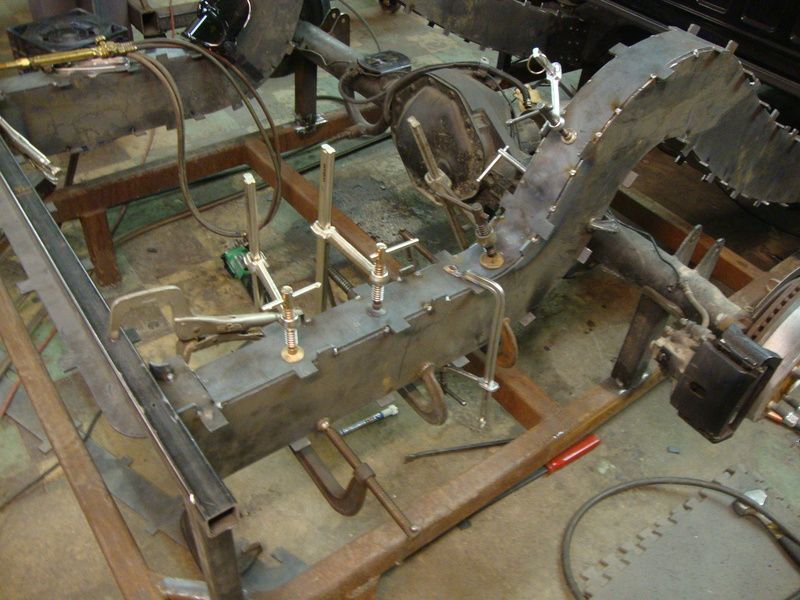

If you haven't seen it yet, check out #7 on the link below, from the inventor of the original, Magnabend. It shows some helpful hints on getting more out of the machine, especially the part about filling any gaps so everything stays parallel to the bed. Also, when it appears you are exceeding the capability of the machine (who....me?), I always stack about three or so of the plates together, more for the magnet to hold onto.