You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Auto Rod Tech's Project Thread

- Thread starter Chad.S

- Start date

danp76

Oldtimer

Great work Chad!...what clear are you using? Do you double clear or just one session of clear?..how many coats? Do you always use the same clear for all your projects?Chad.S said:

B

black88coupe

Looks good. Sub'd to your YouTube page.

Chad.S

Oldtimer

chevman;n74917 said:Chad, are you using an after market frame? Just wondering why you eliminated the body mounts in the front part of the trunk on the 57.

I am using the factory frame. and we will be adding the floor mounts in later. I didn't realize that they got added in later so I didn't locate that hole location as well as some of the others. I just used that location on the jig as a location to help support weight.

B

Bob Hollinshead

Chad, the suspension and frame work looks killer! where do you buy the rectangular tubing bends? what steering box do you plan to use? and are ya planning to run a panhard bar in the back or watts link? Nice work!

Chad.S;n73742 said:No, I am going to epoxy it, but I took the quarters, rockers rear panels and basically everything else off so that way I will have access to spray everything.

then I will epoxy the back sides of the quarter panels as well before I install.. You still have the worry of rust at the spot welds but i don't know any way around that one.

I guess you could dip after welding but it's something I have never done nor would I even know where to begin.

Is there a reason for not using bonding adhesive? The inner rockers have a drain hole for the water to escape.

Chad.S

Oldtimer

I'm not a big fan of bonding adhesive, and I am surely not going to bond the whole car together, It's not like I am only installing one panel. I am also not a big fan of bonding adhesive, I've seen to many failures with it, I've seen it not cure fully before, I've seen quarter panels that were installed with it and only welded at the sail panel and after a accident the only part that was still attached to the car was the welded sail panel. I feel the adhesives have their place just not here so much, I also feel that these cars were welded from the factory and when a client is paying me to restore his car, I don't think he would be to happy if I told him I glued it together.chevman said:Chad.S;n73742 said:No, I am going to epoxy it, but I took the quarters, rockers rear panels and basically everything else off so that way I will have access to spray everything.

then I will epoxy the back sides of the quarter panels as well before I install.. You still have the worry of rust at the spot welds but i don't know any way around that one.

I guess you could dip after welding but it's something I have never done nor would I even know where to begin.

Is there a reason for not using bonding adhesive? The inner rockers have a drain hole for the water to escape.

One of the few places I use adhesive is over the wheel wells on standard duty, (half-ton) trucks, that tends to be a area to rust out and it's not as structural as say a rocker panel, however I did this on my personal truck when I put bed sides on it, and one side cured and one side didn't. Same tube.

In the end there are just to many variables, when it's welded, I know it's not coming apart, which allows me to sleep at night.. If I had it my way I would have a high end spot welder to replicate the spot welds per factory and save on time punching holes and grinding, but I haven't decided I want to spend the money yet, nor am I 100% confident in them. I had my eye on a nice pro-spot machine that was on Ebay used, and looked like new, but I never called on it.

B

Bob Hollinshead

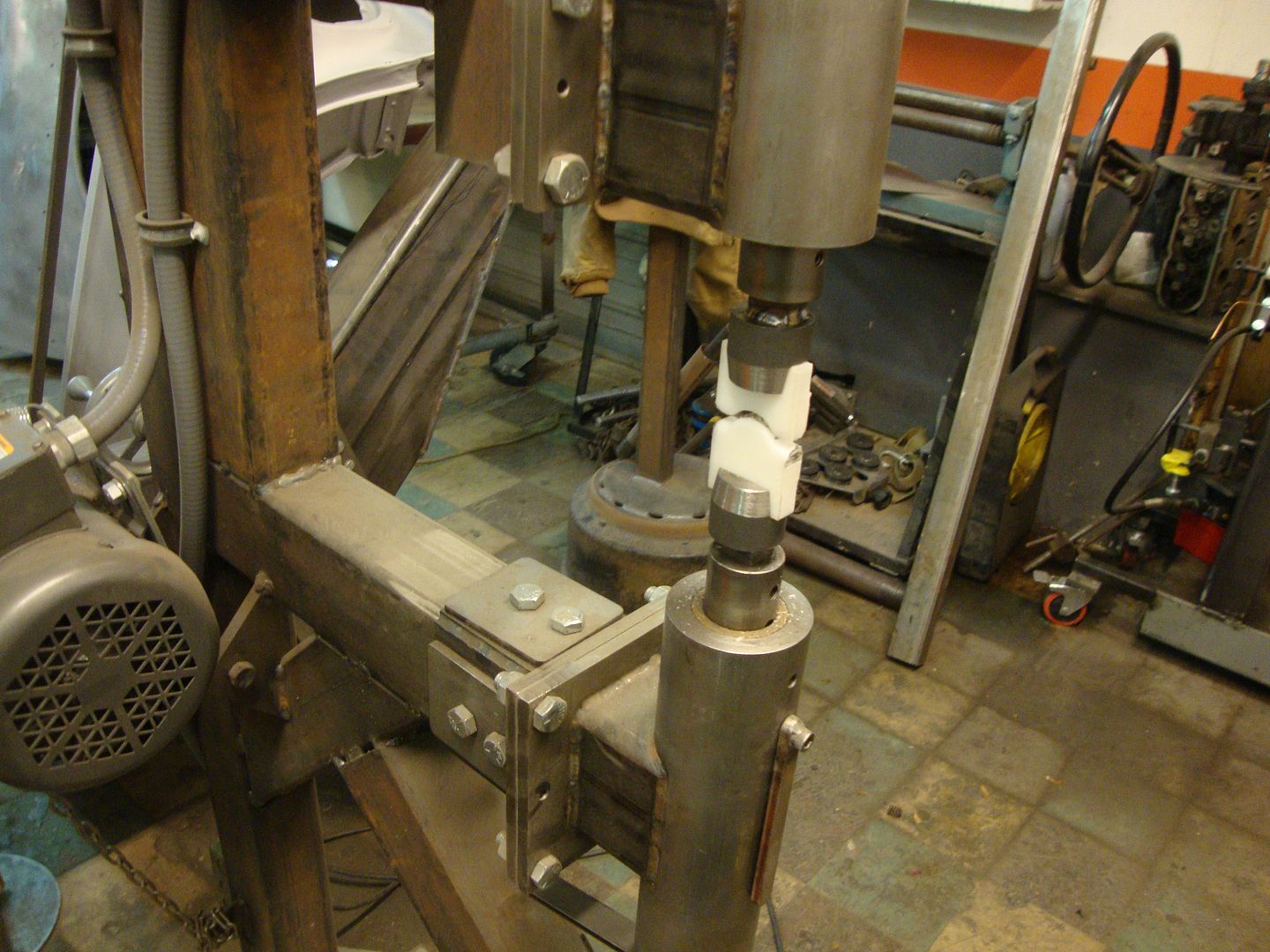

Nice! did you make the dies out of delrin? Nylon?

B

BC928

And I'm fretting about how to 90 degree bend an aluminum Porsche fender to match a later bumper. Wow. Great stuff.

Chad.S

Oldtimer

Thank you sir!!DATEC said:Beautiful job Chad.