You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Auto Rod Tech's Project Thread

- Thread starter Chad.S

- Start date

Chad.S

Oldtimer

underdog;41565 said:That's a beast.

What did you use for the 90 on the bottom and top? Angle iron?

The bottom is basically angle iron with a plate to re-enforce it. I bought that part from Swag, and built everything around it.. It is cheap enough to buy it from them that it's probably not worth making.

- - - Updated - - -

crashtech;41568 said:Looks pretty buff. Wouldn't want it to fall on my toe.

Took three guys just to flip it when I was welding the different sides.

Chad.S

Oldtimer

Oh man, that would be very hard for me to do, I could probably try on the next door skin I make but there is a lot to it, it would be hard for me to explain without some hands on teaching.

Here is a few more pics, I decided to stay late tonight and adjust the edges for MY body line gap and to tip the edges.. It's starting to look like something now.

Here is a few more pics, I decided to stay late tonight and adjust the edges for MY body line gap and to tip the edges.. It's starting to look like something now.

'68 Coronet R/T

Oldtimer

You must have a fairly large brake for those bends. I would have to make it in two halves.

Very nice work. I enjoy seeing the progress you are making.

Very nice work. I enjoy seeing the progress you are making.

Chad.S

Oldtimer

[QUOTE='68 Coronet R/T;42043]You must have a fairly large brake for those bends. I would have to make it in two halves.

Very nice work. I enjoy seeing the progress you are making.[/QUOTE]

I have a 8' brake.. The last bend was really close to previous bend so I had to do that one on the tipping wheel..

I'm anxious to pick up a magnetic brake but I'm really starting to run out of room here and I have no plans to get into a bigger building.

Glad you enjoy watching, I sometimes wonder if I should post or not.. I guess that's the benefit of keeping things in one thread. It's easier to watch or ignore if you don't want to watch it.

Very nice work. I enjoy seeing the progress you are making.[/QUOTE]

I have a 8' brake.. The last bend was really close to previous bend so I had to do that one on the tipping wheel..

I'm anxious to pick up a magnetic brake but I'm really starting to run out of room here and I have no plans to get into a bigger building.

Glad you enjoy watching, I sometimes wonder if I should post or not.. I guess that's the benefit of keeping things in one thread. It's easier to watch or ignore if you don't want to watch it.

'68 Coronet R/T

Oldtimer

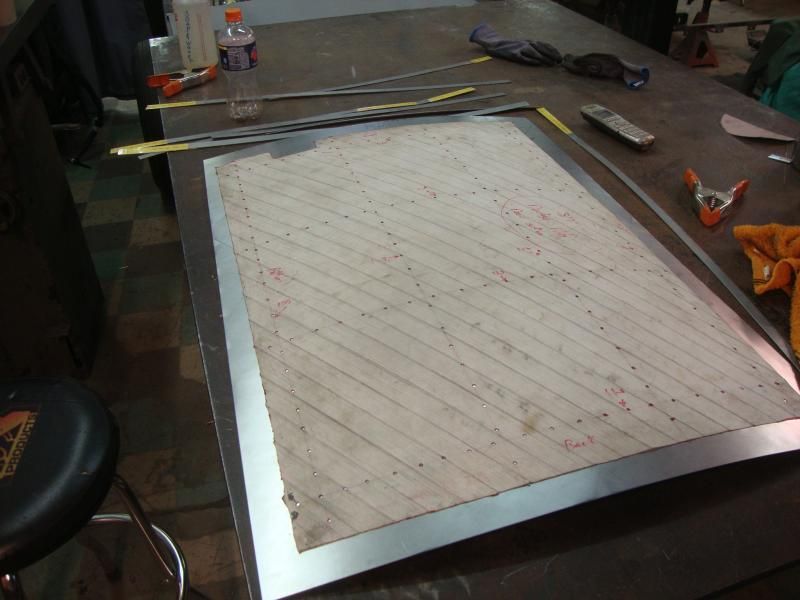

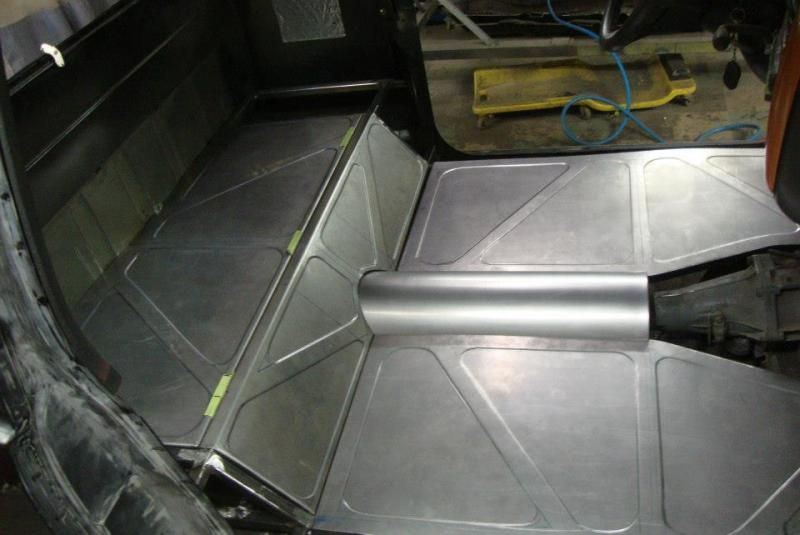

Did you fab those floor pans?

Is so I am guessing you have a very large machine to stamp them like that. Looks fantastic.

Is so I am guessing you have a very large machine to stamp them like that. Looks fantastic.

Chad.S

Oldtimer

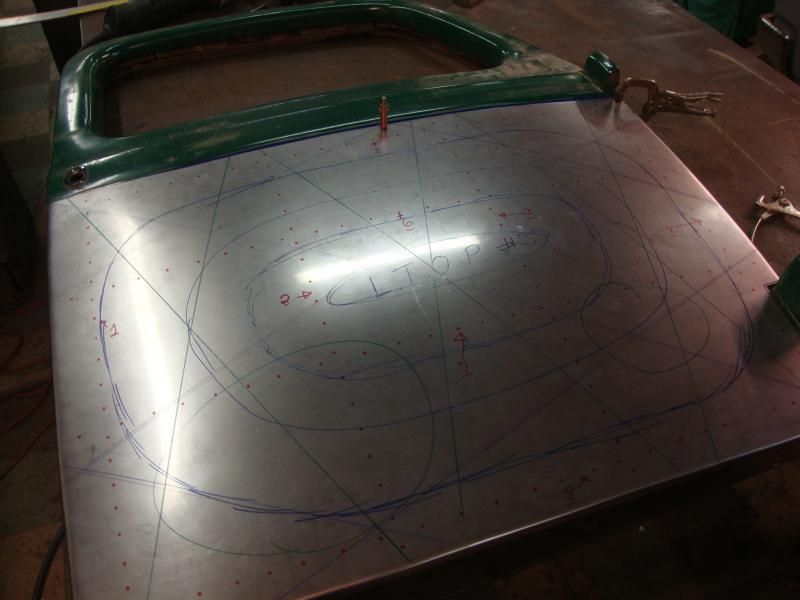

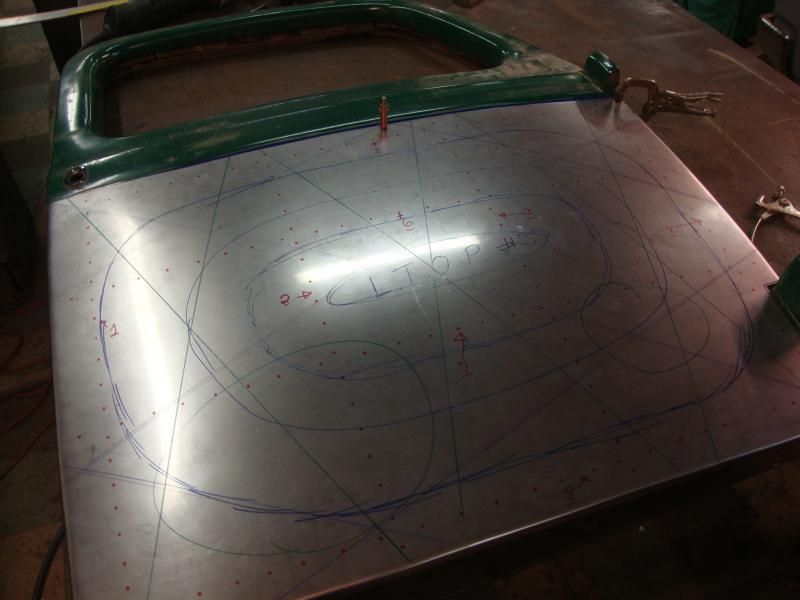

Made a door skin for the passenger side. I had to adjust the edges again because the original door didn't fit the cab opening very well. and the bottom of the door was rusty, along with needing to make a new inner.. This seemed to be a much easier way than doing all of those little adjustments and still needing a bottom. Upon typing this I also realized I have to raise the lower edge, to widen the lower body line.. Oh well.. Still less work than rebuilding the original.