You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Harder body filler for metal.

- Thread starter jlcustomz

- Start date

All_Metal is an excellent product I have been using it for probably 20 years.so I was recently looking at Duraglas, and someone recommended ALL_METAL(aluminum base filler). Anyone have any experience using either of these, I was going to buy Duraglas to fill in a patch panel area, so I was thinking it could be used for the quarter to roof seam as well.

Also what is best method, sand epoxy down to metal, or scuff and apply? Ive been told by a few people that fillers will adhere to SPI epoxy...still skeptical.

The only thing that I have sometimes experienced it's a little finnicky going over epoxy. I have not had a chance to try it over SPI epoxy,it may do well with it.

giggity

Promoted Users

googled it, its high heat polyester filler?P 17

Jim C

Oldtimer

P17 is some bad ass stuff. Yes high heat. I believe its rated to something like 450deg. Its a structural plastic when cured so it will have strength without being bonded to a surface unlike regular body filler. Its a solid plastic when its cured much like straight fiberglass resin or epoxy. Its been around for 20+ years. Its big in the marine and aerospace industry. Doesnt shrink and cures hard. It is much harder to sand than regular bodyfiller so its not something you really want to use as your main filler to skim and flatten panels unless you like sanding. Super sticky and bonds to just about everything.

Well you had mentioned a quarter to roof seam, that's a fairly structural area and P17 would work great there as would All Metal, but being as you have limited thickness there and couldn't cover the all metal with a lot of filler I'd be inclined to use P17 as it's polyester already and primes well. Only imho...

I think there is a hight heat version as well as a regular version, main thing is it's pretty structural, that seam is gonna move some. I pulled a new paint job out in the sun last week and in no time my temp gun read 150 degrees on the hood!

I think there is a hight heat version as well as a regular version, main thing is it's pretty structural, that seam is gonna move some. I pulled a new paint job out in the sun last week and in no time my temp gun read 150 degrees on the hood!

Last edited:

Jim C

Oldtimer

All these different fillers can go direct to metal as well as spi epoxy. I personally always used all metal direct to metal though...mostly. On an occasion i would put it over epoxy. Like i said i would usually just smooth over welds with it if needed before i went to regular filler

giggity

Promoted Users

Was it sealed after you applied it? I've read you apply all metal, sand it, apply sealer, then come back with regular filler.I used All Metal in the roof/quarter area that was originally lead on a 69' z28 and it ghosted like crazy. This was over 10 years ago and the owner didn't want to pay for lead or have the metal strip welded in. Now they don't get an option. My way or the highway.

All Metal is USC. I've never tried the metal 2 metal.i have never had it ghost on me. it actually ghosts less than any filler i have used HOWEVER i dont believe it was all metal. its been a long time but i was using the evercoat stuff which i think is metal-2-metal? all metal is usc right?

giggity

Promoted Users

I had a rookie mistake using all metal. I mixed it exactly as the instructions said, and it cured within 30 seconds.

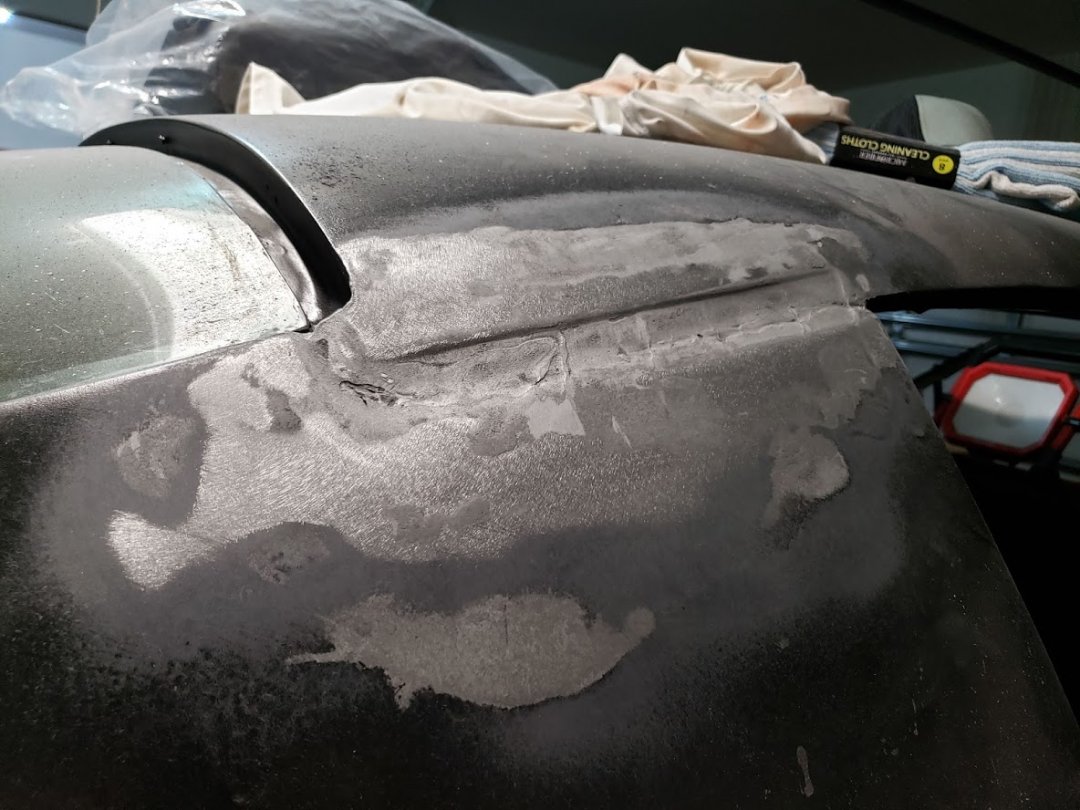

you can see here where it cured too quick. instructions said 3 minutes, but it was very hot and humid when i applied it. apparently temperature affects the cure time....who knew..ha!

I mixed in less hardener here and it spread good.

here I put less hardener in and when i started sanding it about 3 hours later, it was still gummy.

you can see here where it cured too quick. instructions said 3 minutes, but it was very hot and humid when i applied it. apparently temperature affects the cure time....who knew..ha!

I mixed in less hardener here and it spread good.

here I put less hardener in and when i started sanding it about 3 hours later, it was still gummy.