You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

T

TransAm_Stan

Thanks gentlemen!

Stan

Stan

B

Bob Hollinshead

All fillers should go over epoxy IMO. And NEVER apply fillers over an open seam. Weld that sail panel seam up solid if you're going to use filler. And if you ever use body solder on an area like this weld it solid or make sure the solder flows through the seam so there's no chance of trapped acid-I learned the hard way on that, also explains why some factory roof joints failed early and others lasted a long time-all depends on who did the solder job and if they flowed the solder through the joint.

J

jeremyb

Bob Hollinshead;17035 said:All fillers should go over epoxy IMO. And NEVER apply fillers over an open seam. Weld that sail panel seam up solid if you're going to use filler. And if you ever use body solder on an area like this weld it solid or make sure the solder flows through the seam so there's no chance of trapped acid-I learned the hard way on that, also explains why some factory roof joints failed early and others lasted a long time-all depends on who did the solder job and if they flowed the solder through the joint.

x2!! All those factory leaded seams get welded solid then epoxy. Don't forget to get the inside also. I've used kitty hair/evergalss with good results finished out with marson platinum. I only use those types products from Evercoat. Lately I've been using the 870 though after I had some leftover from the black vette. I really like using it more, and for sure is a better product. Even though it might cost a bit more, worth it....definately will be using it from now on.

B

Bob Hollinshead

I haven't used the 870 since the days of splicing header panels was common in the bodyshops-(80's), never had the opportunities to do much vette work back then. If you guys think it's better than Everglass (which has never let me down) I might have to give it a try. What's better about it? The fillers? The resin? Flexibility? Adhesion? If I remember right it doesn't sand that great.

B

Bob Hollinshead

Here's the MSDS sheets on 870 and Everglass for comparisons:

870 http://www.evercoat.com/imgs/msds/100870%20Vette%20Panel%20Adhesive%208-26-2011.pdf

Everglass http://www.evercoat.com/imgs/msds/100622%20Everglass%208-26-2011.pdf

So it looks like:

Polyester resin for both in the same % by weight

Calcium Carbonate- sea shells, 870 only

Styrene- vinyl same % by weight

Magnesite- Magnesium Carbonate, mineral, rock...870

Quartz- mineral, rock, 870

Dolomite- Calcium Magnesium Carbonate, mineral, rock...in Everglass

Inert Filler- probably the sandability aid in Everglass or the glass?, proprietary

Maybe it's all the sea shells and minerals in 870 that makes it sand so hard?

I remember a DuPont lacquer primer many years ago that used sea shells in it and it sanded hard!

870 http://www.evercoat.com/imgs/msds/100870%20Vette%20Panel%20Adhesive%208-26-2011.pdf

Everglass http://www.evercoat.com/imgs/msds/100622%20Everglass%208-26-2011.pdf

So it looks like:

Polyester resin for both in the same % by weight

Calcium Carbonate- sea shells, 870 only

Styrene- vinyl same % by weight

Magnesite- Magnesium Carbonate, mineral, rock...870

Quartz- mineral, rock, 870

Dolomite- Calcium Magnesium Carbonate, mineral, rock...in Everglass

Inert Filler- probably the sandability aid in Everglass or the glass?, proprietary

Maybe it's all the sea shells and minerals in 870 that makes it sand so hard?

I remember a DuPont lacquer primer many years ago that used sea shells in it and it sanded hard!

D

Deleted member 7

This has been a very good thread.. I have always used USC over the Evercoat.. I bought a couple of tubes of Fiber Tech from Evercoat and it failed, so I went back to the USC and never gave it another thought.. I also cover over welded seams like on sail panels with the evercoat.. I thought about welding in metal like Bob says he does, but have never done it..

So Shine, you say the 870 which I have here, works better for filling in said seams than one of the " fiberglass" products correct?? Just making sure, i dont wanna go back and read again

Im lazy this morning..

^^^ This is how I normally fill the quarter roof seam

So Shine, you say the 870 which I have here, works better for filling in said seams than one of the " fiberglass" products correct?? Just making sure, i dont wanna go back and read again

Im lazy this morning..

^^^ This is how I normally fill the quarter roof seam

crashtech

Combo Man & Mod

shine;17101 said:if i have to use everglass i will lead the sucker .

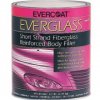

Shine, I want to make sure we are talking about the same product. Is is this exact one you have had problems with?:

It is #632, and where I have had the Duraglass in the white can do bad things, the above product has been OK, though I don't use much of it. I don't believe they are all created equal.

shine

Member

over the years i have tried many. i just dont like the way they will ghost. the 870 is pretty much the go to filler on corvettes. that and using epoxy resins.

the glass fillers just seem too soft to me. i dont have any long term luck with them so i will avoid them. i have to live with these cars i build for a long time.

sorry crash but no i have not tried that filler. at least not in that wrapper ....

the glass fillers just seem too soft to me. i dont have any long term luck with them so i will avoid them. i have to live with these cars i build for a long time.

sorry crash but no i have not tried that filler. at least not in that wrapper ....

B

Bob Hollinshead

I might have to do some product comparison testing when the summer sun returns. One thing I've noticed is lapped seams will ghost more often than a butt welded seam. Maybe it's the extra metal=more heat transfer.

B

Bob Hollinshead

chevman;17099 said:I called evercoat and they said to use everglass in the seams to prevent cracking, and after sanding, top it off with 870 to prevent ghosting.

Based on the Evercoat recomendation it sounds like Everglass must be a stronger product? or more flexible? But if they recomend 870 over the top there must be some benefit-like it provides a shell? or heat barrier?

shine

Member

heat and expansion. this is why many patch panels ghost back. same with fiberglass. imho all of the chopped glass products react to uv and heat. they swell when exposed and shrink back when cooled. on my next vette project it will get it's repairs then set in the sun for at least a week. then it will get resurfaced. but all work will be done in epoxy.