You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1941 chrysler coupe build

- Thread starter 123pugsy

- Start date

1A Rock

Promoted Users

Glad to see some updates, I was worried this had fell into the "Land of Undone"! Great work.Next was to get the cowl patched up so the firewall could get started.

View attachment 17278

View attachment 17279

View attachment 17280

View attachment 17281

View attachment 17282

View attachment 17283

View attachment 17284

MJM

Promoted Users

Holy fabrication Batman !!! You sir have some serious skills. I had no idea you had a restoration thread going, and I do a lot of reading here. Read this thread from the start and what a roller coaster of emotions I felt, from excitement, to amazement, to sadness. Then it hit me, perfection is your guiding light and it shows.

I greatly enjoyed reading this thread and will be looking for it from here on out.

Thanks for sharing !!!

I greatly enjoyed reading this thread and will be looking for it from here on out.

Thanks for sharing !!!

123pugsy

Member

Glad to see some updates, I was worried this had fell into the "Land of Undone"! Great work.

Thanks.

I never give up. I ended up stopping to do body work and paint on my El Camino over the winter.

Lots more to add yet. I have an interesting firewall coming up so stay tuned.

123pugsy

Member

Holy fabrication Batman !!! You sir have some serious skills. I had no idea you had a restoration thread going, and I do a lot of reading here. Read this thread from the start and what a roller coaster of emotions I felt, from excitement, to amazement, to sadness. Then it hit me, perfection is your guiding light and it shows.

I greatly enjoyed reading this thread and will be looking for it from here on out.

Thanks for sharing !!!

Thanks. Robert does perfection. I do just enough to get close to the shapes needed and then will gladly use some Bondo to get the final shapes.

123pugsy

Member

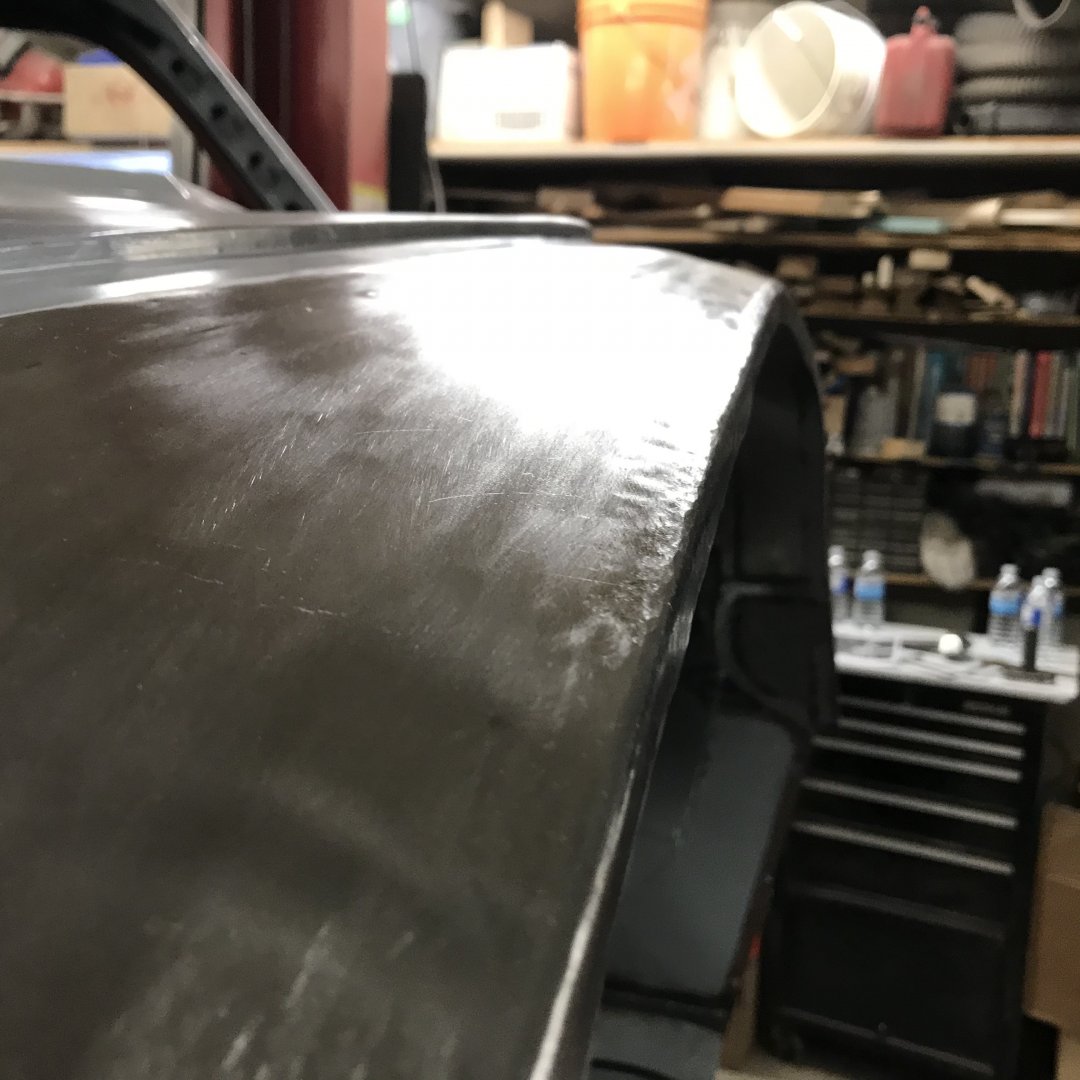

And of course like every other piece I've made (other than stuff done on the press brake), the shape was off again.

Look closely for the bright light coming thru in the first pic. The plywood board is reasonably flat.

Slice, dice, and weld to correct.

Also, move the bends using a hammer and dolly. This leaves some bad bumps.

No gaps now, although, the nice panels I started with are quite mucked up.

Look closely for the bright light coming thru in the first pic. The plywood board is reasonably flat.

Slice, dice, and weld to correct.

Also, move the bends using a hammer and dolly. This leaves some bad bumps.

No gaps now, although, the nice panels I started with are quite mucked up.