Treeslayer

Mike

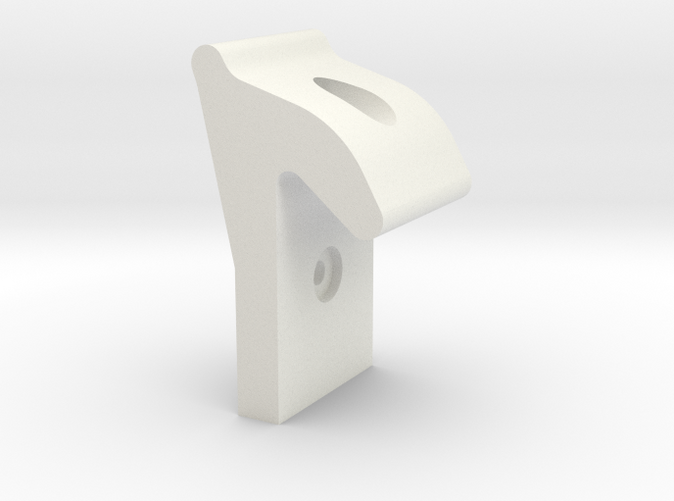

Jim did you replace the hinge mounts? im gonna have to repair the door hinge mount on a cab for my next project. if i ever get to it.

im thinking i may be able to drive it back down, tack and put a reinforcement patch on the back side. maybe.

im thinking i may be able to drive it back down, tack and put a reinforcement patch on the back side. maybe.