8

82firebird

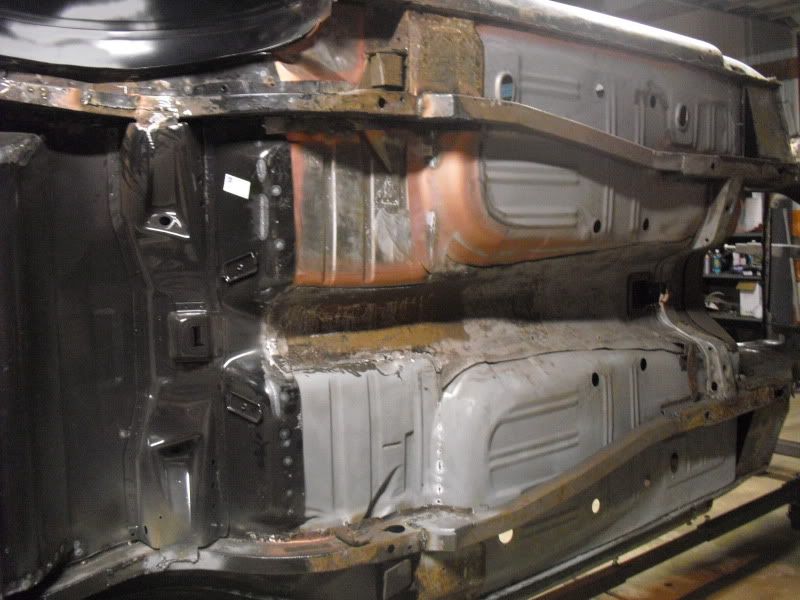

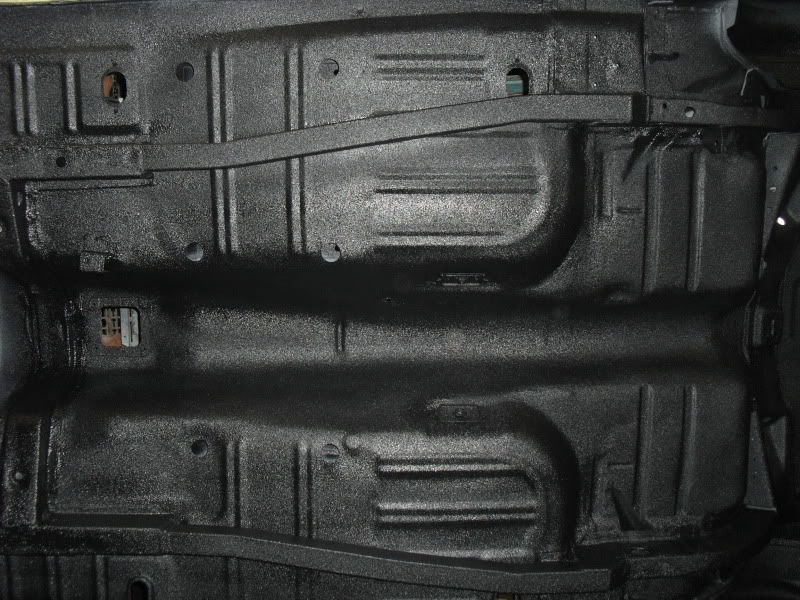

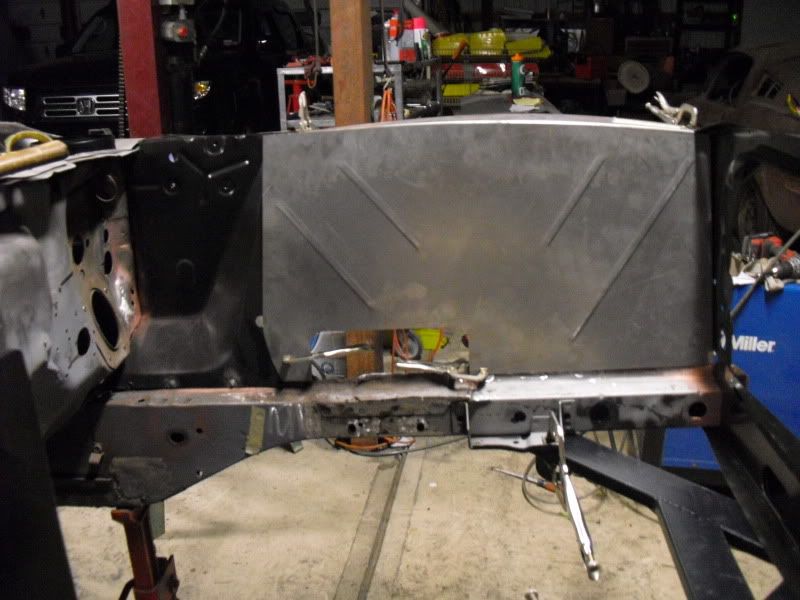

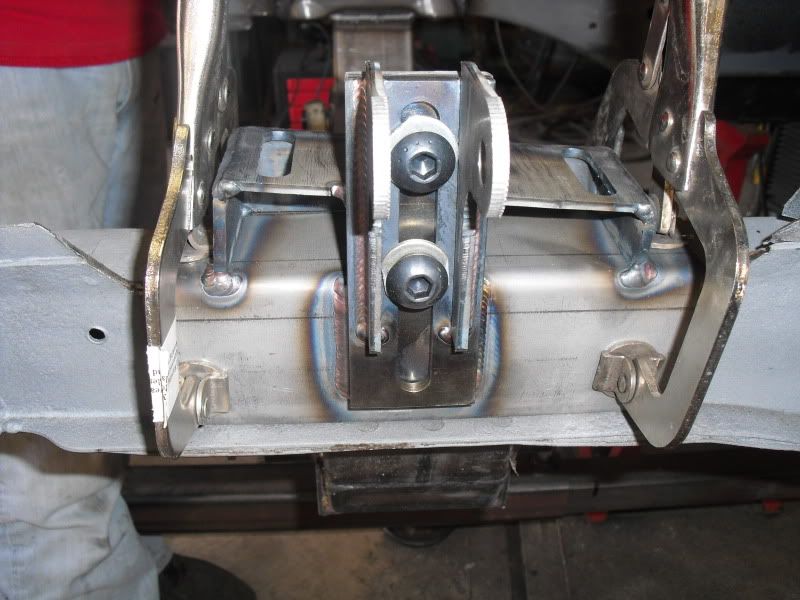

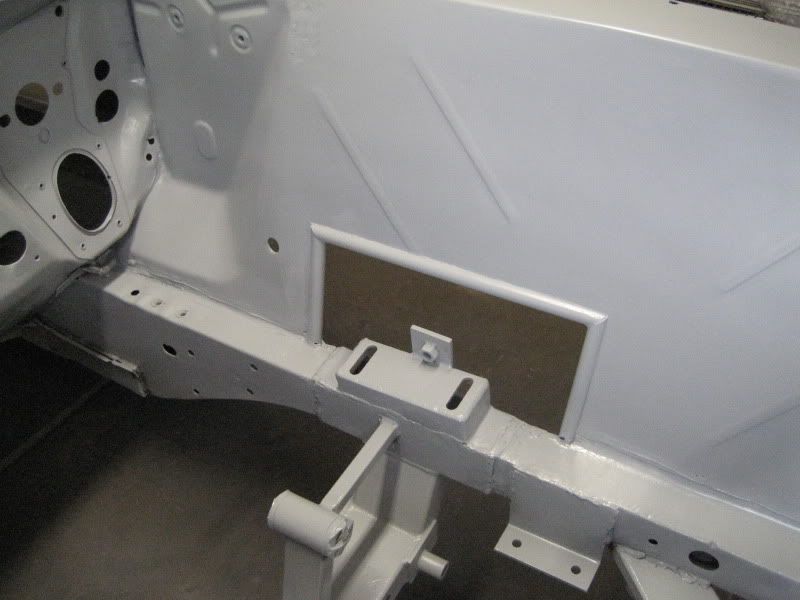

My wife has always loved the 67-68 Fastback body style and decided to make her first into an Eleanor, her dream car. The car should have been crushed it was in such bad shape. We both have full time jobs so we work on the car when we can. This is our first project of this level in terms of replacing panels, etc. We have learned quite a bit and met many great people who have helped us along the way.

Day 1:

Day 1: